Issue with 3d cutting and stepping to one side of project

I think Im getting further - and learning, still having issues though. Managed to get all 6 tool paths to cut (after a fashion) but with issues

Bits Ooznest start bit set

1 Initial 3d roughing pass seemed to work just fine

- Bit 1/4 -(6.3 mm) End Mill 2 flute up cut)

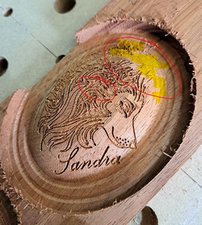

2 Finishing pass had issues see the images – the 2 plaques where laid out end to end

- The finishing pass seemed to worked fine for the lower right corner and side of each plaque but produced a stepped effect on the opposite side and top portion of each

- The central dome seems to be a little off centre

- 1/8 (3.175 mm) ball nose 2 flute up cut

3 The engraved dog face would have cut fully across the dome but for the stepping issue, but did have material removed that the software said would remain

- I think that the dome should have a lower angle on it

- Removing some if the image clutter might help with the unwanted material loss

- V Bit 30 degree –(1/4 - 6.35mm) Ooznest call this a calibration bit?

4 The names seemed to be fine just a little too deep

- V Bit 30 degree –(1/4 - 6.35mm) Ooznest call this a calibration bit?

5 The holes did not go all the way through

- 1/8 (3.15mm) end mill 2 flute up cut

6 The final cut out went through in places but not in others possibly the wood not being quite level

- 1/8 (3.15mm) end mill 2 flute up cut

All the bits are from Ooznest starter set

Any help welcome - although I do count this as progress and have learnt a bit more from the failure

Update (04/27/2024)

Have added the project file for additional information Wolf

Is this a worthwhile discussion?