Introduction

Please read before proceeding to avoid damaging the controller and voiding your warranty

- Avoid connecting the Controller via USB when you do not need to. (Except when instructed to in the guides)

- Always unplug the WorkBee Power Supply before connecting the USB Cable.

-

-

The Emergency Stop has been pre-tested by Ooznest. But you should test it again.

-

First insure the machine is switched on, and have WorkBee Control open on your web browser.

-

Press the Emergency Stop.

-

You should loose connection to WorkBee Control.

-

If you do not loose connection make sure the USB Cable is not plugged in.

-

If you still do not loose connection, stop here and Contact Us.

-

With the connection lost, unlatch the Emergency Stop.

-

After a few seconds WorkBee Control should reconnect.

-

-

-

If looking at the machine from the front the axis motion is:

-

The X-Axis is positive towards the right.

-

The Y-Axis is positive towards the back.

-

The Z-Axis is positive going up.

-

-

-

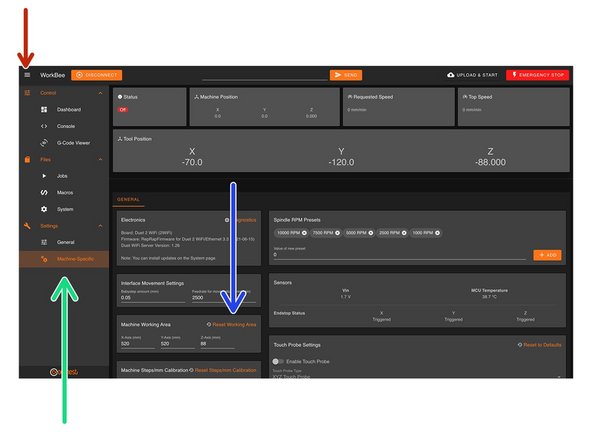

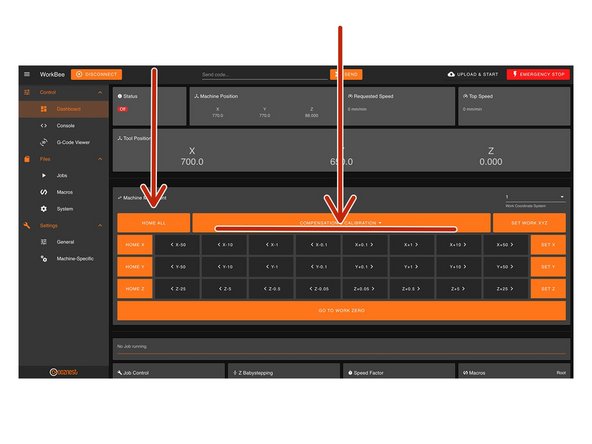

In WorkBee Control open the Navigation Menu

-

Under 'Settings', press 'Machine Specific'

-

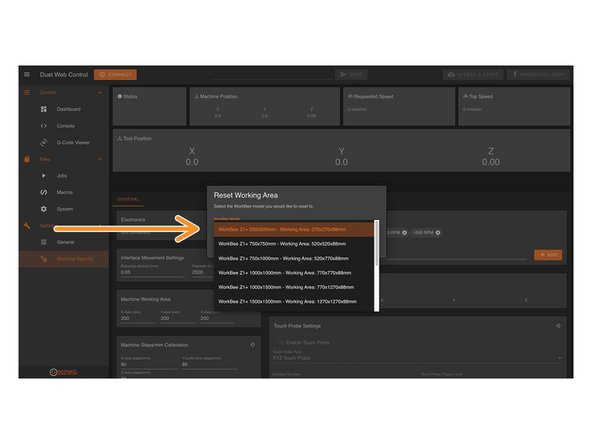

Under the Panel called 'Machine Working Area' press 'Reset Working Area'

-

Under the 'WorkBee Model' dropdown select your machine size.

-

Yours is a Z1+ Model

-

Confirm by pressing 'Yes'

-

The machine is now configured. No restart required.

-

-

-

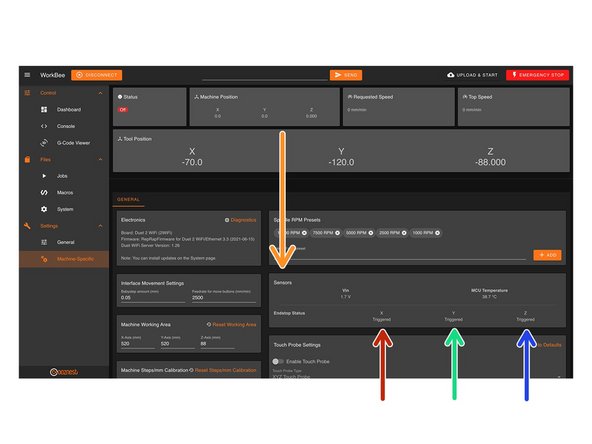

On the same page, under the Panel called 'Sensors' we can test the Limit Switches.

-

Activate the X-Axis limit switch with your finger and hold.

-

The Endstop Status should change to 'Triggered'

-

It is normal for there to be a delay between pressing the limit switch and the status being updated. Please do not be concerned, the board will stop the motor instantaneously.

-

Repeat this procedure for the Y-Axis Limit Switch.

-

Repeat this procedure for the Z-Axis Limit Switch.

-

If any do not behave as intended do not proceed with this guide, please Contact Us.

-

-

-

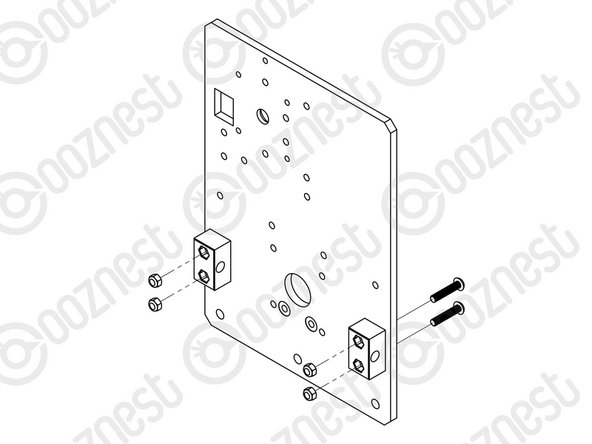

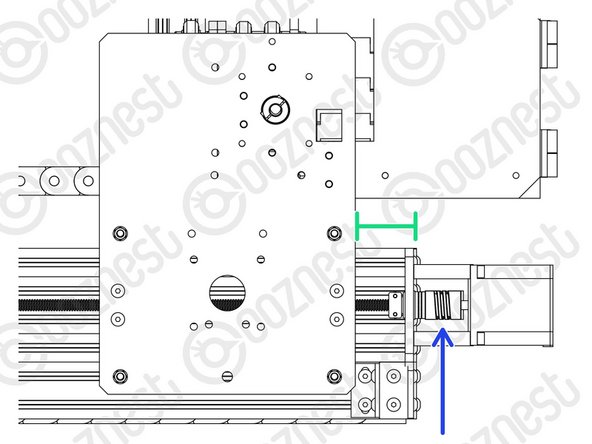

At this point in time, the Nut Blocks on X & Y-Axis Carriages should be loose.

-

Tighten these.

-

Do not over tighten them, they will need to be undone shortly.

-

-

-

When the machine homes, it will raise the Z-Axis, and then move the X and Y-Axis to the far right-hand corner.

-

If any of the points below do not behave as explained do not proceed with this guide, please Contact Us.

-

Press Home Z. The Z-Axis should raise upwards, bounce once on the limit switch, and then stop.

-

Press Home X. The Z-Axis should home like the previous. The X-Axis should then move towards the right, bounce once on the limit switch, and then stop.

-

Press Home Y. The Z-Axis should home like previous. The Y-Axis should then move towards the back, bounce once on the limit switch, and then stop.

-

Press Home All. The Z-Axis should home like previous. Then the X and Y-Axis should home like previous.

-

-

-

Home the machine and use the jog buttons to move the machine roughly into the middle of the working area in X & Y.

-

Leave the machine powered on so the Stepper-Motors stay locked.

-

If at any point in Step 7, 8 or 9 you loose power to motors and need to re-lock the motors, go to Control > Console and send the command 'M17'

-

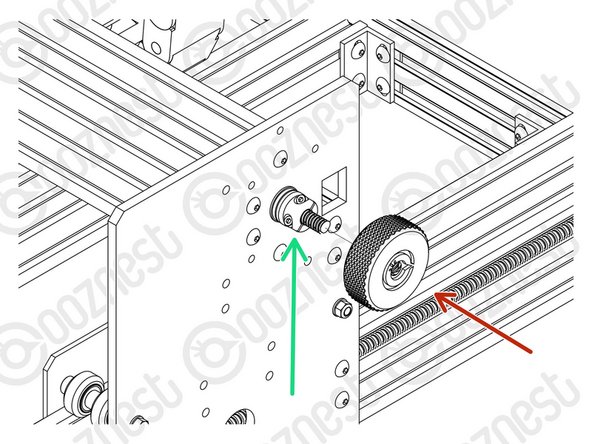

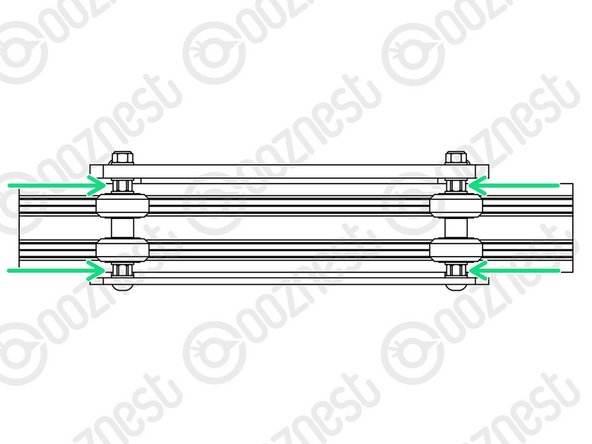

Loosen all the Nut-Blocks on the X & Y-Carriages.

-

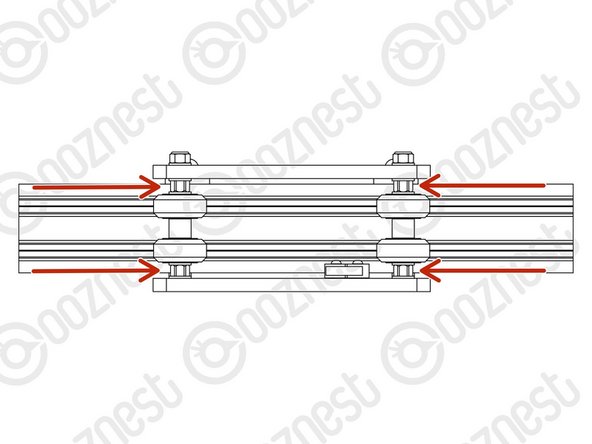

Loosen the Clamping-Collars that are on the inside channel of Extrusion-E/F on the X & Y Axes.

-

Move the Rubber-Bushings & Clamping-Collars away from the plates.

-

-

-

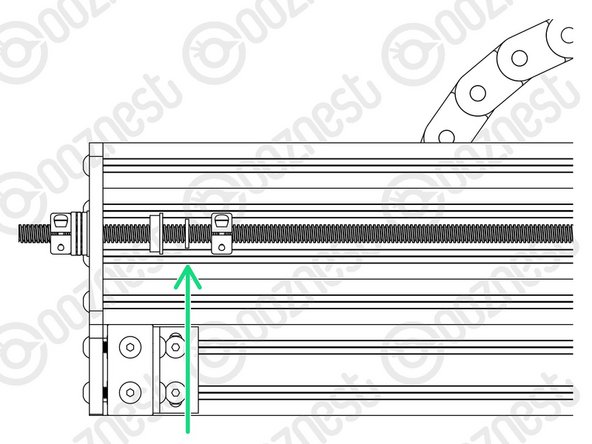

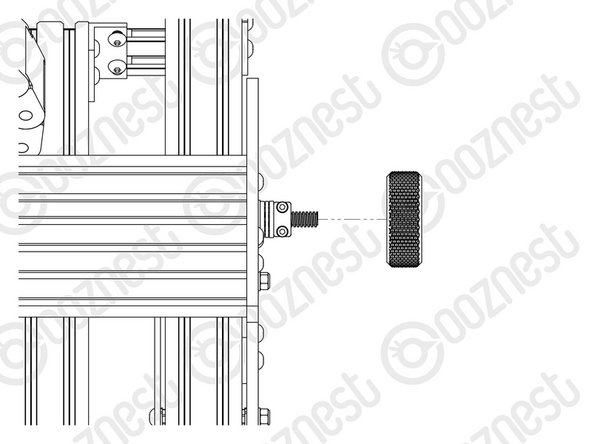

Starting with the X-Axis, thread on the Tensioning-Knob until it is up against the Clamping-Collar.

-

Then loosen the same Clamping-Collar.

-

Turn the Tensioning-Knob clockwise, you will feel the Lead-Screw tension build.

-

Keep turning until the Stepper-Motor clicks over.

-

Keep turning, just before the point that the Stepper-Motor clicks over again is the correct amount of tension for the Lead-Screw.

-

While at this point of tension, tighten the Clamping-Collar that is next to the Tensioning-Knob.

-

Remove the Tensioning-Knob.

-

Repeat all the above for both Lead-Screws on the Y-Axis.

-

-

-

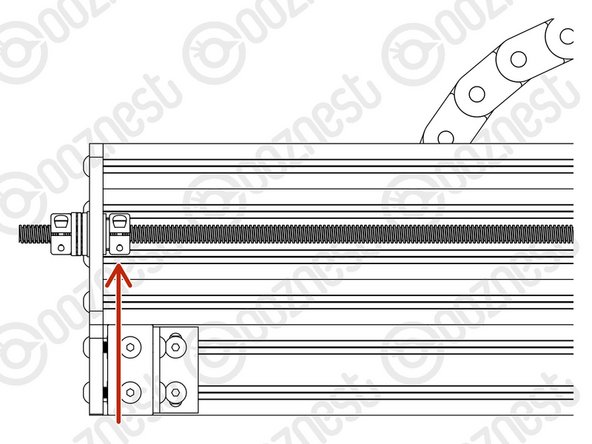

Once all 3 Lead-Screws are tensioned, put back the Flanged-Radial-Bearings, Rubber-Bushings, and Clamping-Collars that are on the inside channel of Extrusion-E/F on the X & Y Axes.

-

The Clamping-Collars only need to be pushed lightly up against the Rubber-Bushings & Flanged-Radial-Bearings. Tighten the Clamping-Collars.

-

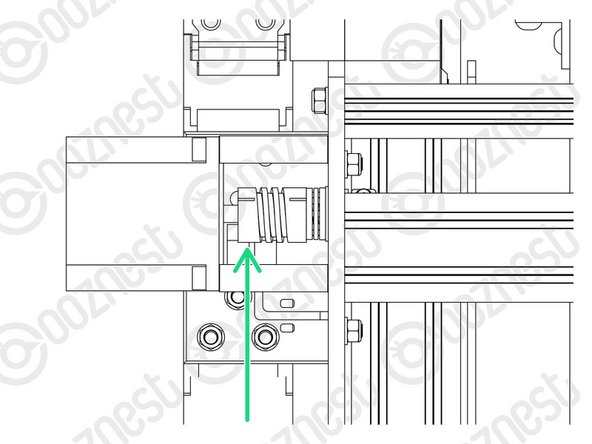

We need to release any tension inside the Flexible-Couplers.

-

On the Stepper-Motor side of the X & Y-Axis Flexible-Couplers completely loosen the grub screws and clamping bolts.

-

Then completely tighten the same grub screws and clamping bolts.

-

Make sure you do this to the Stepper-Motor side of the Flexible-Coupler.

-

If you loosen the Lead-Screw side you will loose all tension in the Lead-Screws and you will need to redo it.

-

Tighten all the Nut-Blocks on the X & Y-Carriages. While doing so, squeeze the Nut-Blocks together to remove any backlash.

-

-

-

Home the machine.

-

Then turn the machine off.

-

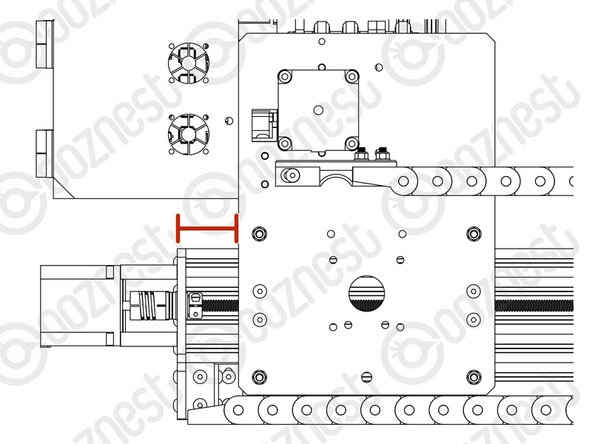

On the left Y-Axis (The side with the Limit-Switch) measure the distance between the back of the Y-Carriage and Y-End-Plate.

-

On right Y-Axis measure the same distance.

-

Rotate the Flexible-Coupler by hand until it matches the left Y-Axis.

-

-

-

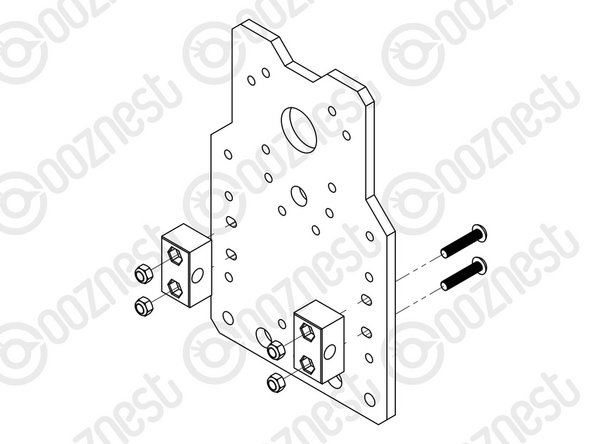

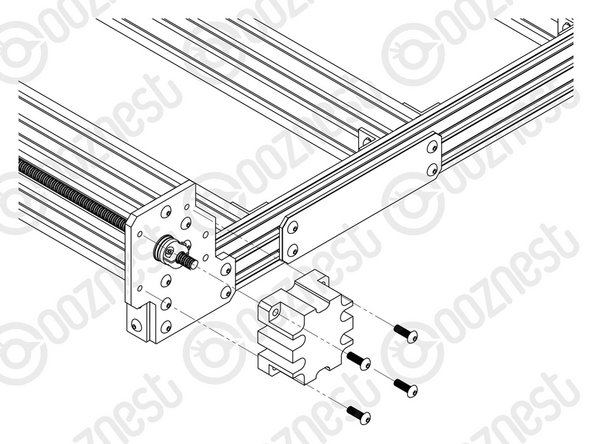

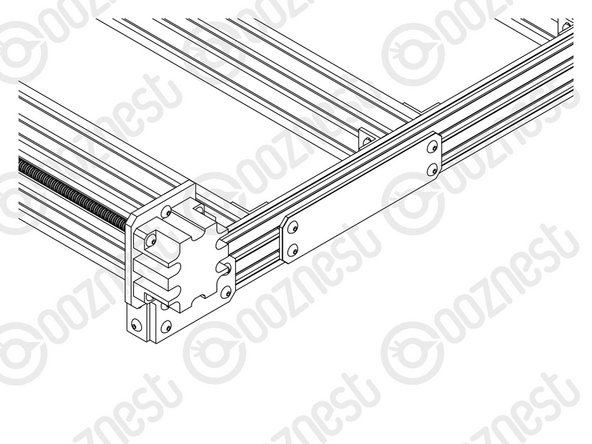

Using 12 x M5-Button-Head-Bolt-16mm attach 3 x Lead-Screw-Caps over the bare ends of the X & Y-Axis Lead-Screws.

-

-

-

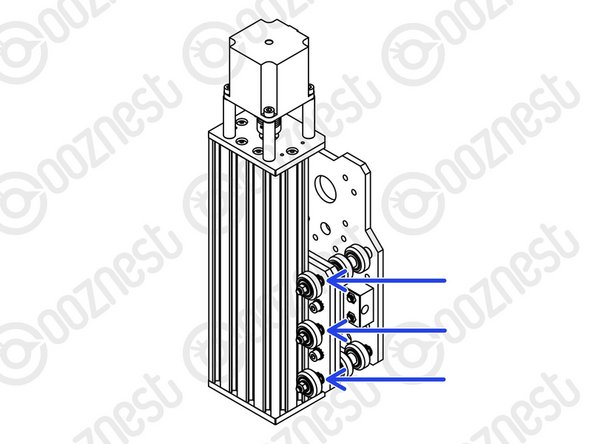

In the 'Extras' box there is an Eccentric-Spacer-Spanner.

-

This is shaped to give you access to all the Eccentric-Spacer-6mms without needing to move your machine.

-

Eccentric-Spacer-6mms should be adjusted until there is a small amount of friction between the Solid-Wheel & Extrusion.

-

Check there is also no play in the carriage if you try to wobble it. The Eccentric-Spacer-6mm will remove this if adjusted correctly.

-

Adjust the Eccentric-Spacers on the X-Carriage.

-

Adjust the Eccentric-Spacers on both Y-Carriages.

-

Adjust the Eccentric-Spacers on the Z-Axis.

-

We recommend periodically checking the Eccentric-Spacer-6mms throughout the use of the machine.

-

-

-

It is nice to finally start moving the machine!

-

Guide Complete - Proceed to 3. Spoilerboard

-

Thanks for following the guide. Testing of the WorkBee is now complete!

Thanks for following the guide. Testing of the WorkBee is now complete!

Cancel: I did not complete this guide.

44 other people completed this guide.

2 Comments

Using 16 x M5-Button-Head-Bolt-16mm attach 3 x Lead-Screw-Caps over the bare ends of the X & Y-Axis Lead-Screws.

This had me hunting around trying to find 16x M5 16mm bolts for a good five minutes before I realised that three caps with four bolts each only needed twelve total. Somehow I only had six, so each one got two.

Jack O'Hara - Resolved on Release Reply