-

-

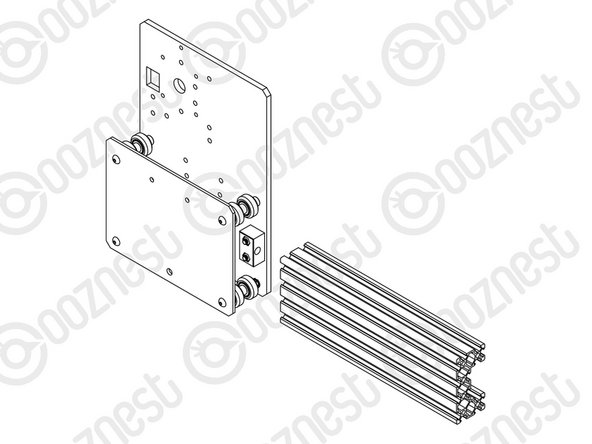

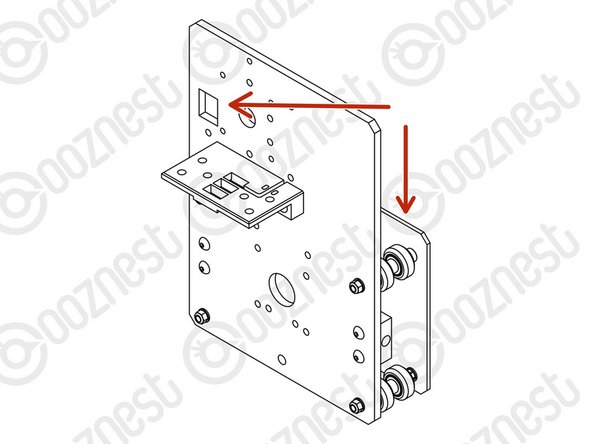

Attach 2 x Nut-Blocks to a Y-Plate-Outer using 4 x M5-Button-Head-Bolt-25mm & 4 x M5-Nyloc-Nuts.

-

Keep these bolts loose so the Nut-Blocks can still move side to side.

-

-

-

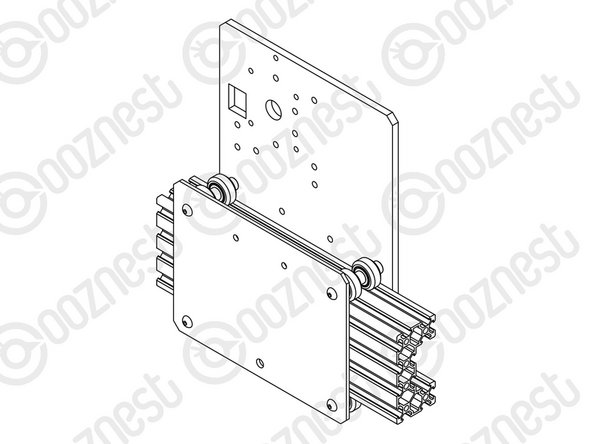

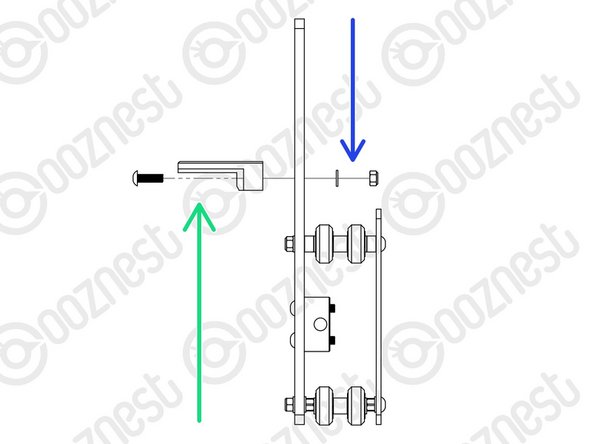

Assemble the bottom right Solid-Wheel set first. Insert a M5-Button-Head-Bolt-60mm through the Y-Plate-Inner

-

On to the bolt add an Eccentric-Spacer-6mm. (Rounded portion into the Y-Plate-Inner)

-

Then add a Precision-Shim - ->- - Solid-Wheel - ->- - Aluminium-Spacer-9mm - ->- - Solid-Wheel - ->- - Precision-Shim

-

Add an Eccentric-Spacer-6mm then a Y-Plate-Outer. (Rounded portion of the Eccentric-Spacer-6mm goes into the Y-Plate-Outer)

-

On the outside of the Y-Plate-Outer add onto the bolt a Precision Shim then a M5-Nyloc-Nut. Only slightly thread on the M5-Nyloc-Nut.

-

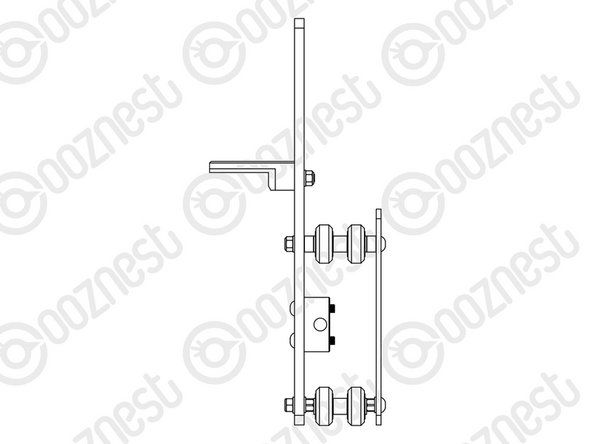

Repeat the above for the other Solid-Wheel set on the bottom row.

-

Repeat for the 2 x Solid-Wheel sets on the top row, but use a Aluminium-Spacer-6mm instead of each Eccentric-Spacer-6mm.

-

The M5-Nyloc-Nuts can now be tightened. Ensure that each Solid-Wheel still rotates freely.

-

-

-

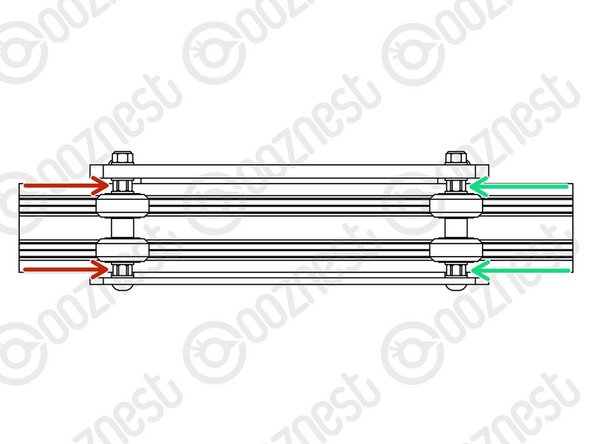

On the hexagonal portion of the Eccentric-Spacer-6mm, there will be a face that is marked with ‘6mm’.

-

Using a 8mm spanner, rotate each Eccentric-Spacer-6mm so that this face is facing downwards. (Doing this maximises the gap between the top and bottom row of Solid-Wheels)

-

Insert Extrusion-D in-between the two rows of wheels. Turn the assembly upside down so Extrusion-D is sitting on the top row of Solid-Wheels.

-

Rotate both Eccentric-Spacer-6mms on one set of Solid-Wheels until there is a small amount of friction between the Solid-Wheels and Extrusion-D

-

Repeat for the other set of Solid-Wheels.

-

Slide Extrusion-D back and forth. This should require a small amount of force, and all Solid-Wheels should spin.

-

Check there is no wobbling of Extrusion-D. Once happy, double-check the tightness of the M5-Nyloc Nuts and remove Extrusion-D.

-

Try to get all the Solid-Wheels touching Extrusion-D as best as possible. If not, it is not a problem, we will check the Eccentric-Spacers-6mms again once the machine is built.

-

-

-

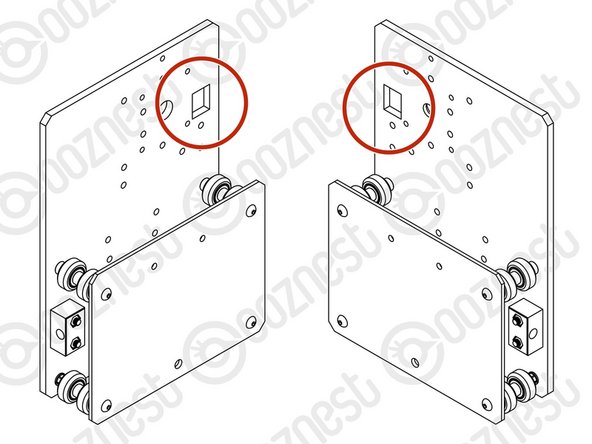

Repeat Steps 1-3 for another Y-Plate Assembly. It should be a mirror image of the previous assembly.

-

Ensure the square cut out on the Y-Plate-Outer is at the back.

-

-

-

A Drag-Chain-Mount needs to be attached to the second Y-Plate-Outer.

-

Make sure you have the correct Y-Plate-Outer.

-

The square cut out on the Y-Plate-Outer is at the back with the wheels on the opposite side.

-

Insert 2 x M5-Button-Head-Bolt-16mms through the Drag-Chain-Mount, then through the Y-Plate-Outer.

-

Then add a 2 x Precision-Shims and 2 x M5-Nyloc-Nuts on the opposite side of the Y-Plate-Outer.

-

Moving forward this will be known as the Y-Carriage-Left.

-

The other one will be known as the Y-Carriage-Right.

-

-

-

The Y-Carriages can be put to one side until later.

-

Guide Complete - Proceed to 3. X-Carriage Assembly

-

Thanks for following the guide. Any issues, please contact us!

Thanks for following the guide. Any issues, please contact us!

Cancel: I did not complete this guide.

101 other people completed this guide.

3 Comments

On page 3 it incorrectly implies that you use ‘eccentric’ spacer 6mm on the top & bottom wheel sets - it should say ‘aluminium’ spacer 6mm (I think?!)

Jim Cooper - Resolved on Release Reply