Hello there!

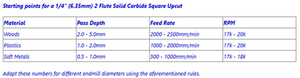

Determining the ideal speeds & feeds varies based on various factors, including the specific end mill and material in use. Still, we can provide some general guidelines.

Rule of Thumb for beginners:

1. Plunge rate: About 50% of your feed rate.

2. Stepover: No more than 50% of the endmill cut diameter.

3. Pass depth: No more than the endmill cut diameter.

NOTE: Remember all the values are related to each other - so if you halve your endmill cut diameter, you will also halve your stepover, pass depth, feed rate, and plunge rate.

4. Endmill Types: Down-cut endmills enhance finish, while up-cut versions offer more production efficiency.

5. Cut Direction: Use climb milling for efficiency and conventional milling for accuracy.

6. Approach ball end mills lightly, focusing on refining the roughing pass leftovers.

7. For engraving or using a V bit, be cautious as the tips are delicate.

8. When uncertain, opt for shallow cuts at faster feed rates.

9. Use Amana Tools Speeds & Feeds table with caution. The RPMs are correct, but their feed rates and pass depths are adventurous at best.

Additional Resources: There are several online speeds and feeds calculators, both free and paid. One such calculator, created by a community member, is available here: https://www.facebook.com/groups/TheCNCGr...

Disclaimer: The recommendations provided are based on general guidelines. We advise conducting your research and tests, considering specific variables like your machine, material, and design. Ooznest Limited assumes no responsibility for any potential damage or broken end mills resulting from the advice in this communication.

I hope the above has given you a starting point, if you have any questions, please don't hesitate to reach out!