x axis set up

Odd problem on my x axis set up

The range of the x axis travel does not seem to be central to the machine

Homing the x axis allows the z axis mounting bracket to collide with one of the nuts on the right hand gantry plate when moving down in the z axis,

The centre of the machine is about 5 mm out from the centre of the cutting area ( 275mm on the 1000 * 750 machine)

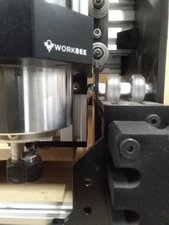

This image shows the x axis homed, you can see that when the z axis is lowered it collides with the nut on the wheel assembly, the distance between the z c-beam and the y plate is about 7 mm

this image shows the x axis at machine position x0 y 0, here the distance between the z c-beam and the y plate is about 17 mm

This picture shows the x axis limit switch correctly fitted -as far as I know

A solution would appear to be to move the limit switch about 5mm away from the y plate but I suspect that there is something in one of the config files that allows the “Bounce” amount after hitting the limit switch to be adjusted.

Anyone have any ideas?

Is this a good question?