Should there be this much movement on my X / Y?

Hello,

After attempting to CNC site contour models, I keep encountering the same issue.

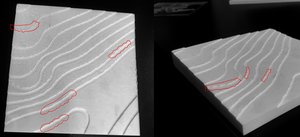

Where contours should be made of smooth curves, the surface appears to have 'teeth' or 'squiggles' across most lines, I have highlighted in red the worst examples.

Having tried different drill bits thickness' and speeds etc with no change, I am getting a bit lost as to what the problem is, although when watching it work, I noticed that the machine seems to have a bit of a judder when changing directions.

Once the job had completed, I turned it off and felt that their seems to be some give/wobble, whereby the wheels can move forward and backward by about 3mm, I have attached a video with sound below to show the movement.

Should the WorkBee have this kind of looseness to it? Should I tighten it somehow? I inherited this machine at my new work place (colleague who set it up has left over a year ago). I would appreciate any advice or link to a guide on getting the correct tension on this axis, and whether this could be impacting the accuracy of my router.

Thank you very much in advance anyone that can help!

Alistair

Is this a worthwhile discussion?