-

-

Make sure you build the machine on a flat surface.

-

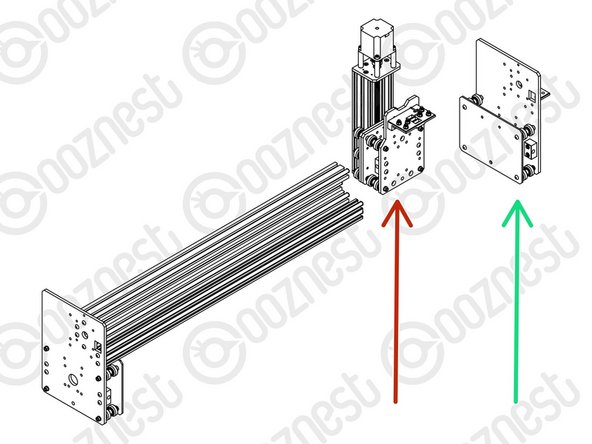

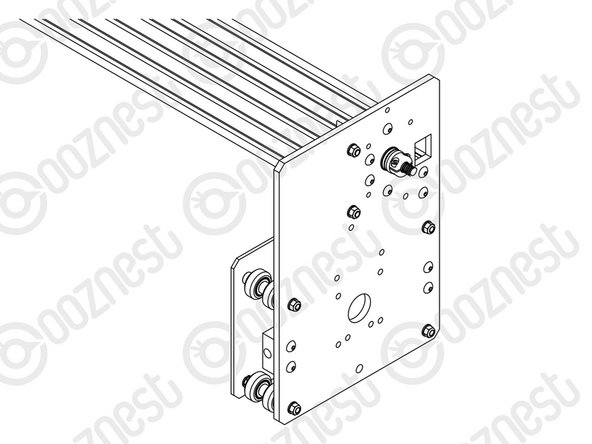

Attach Extrusion-B to the back two holes on the Y-Carriage-Right using 2 x M5-Button-Head-Bolt-16mm.

-

Attach Extrusion-E to the four non-threaded holes on the Y-Carriage-Right using 4 x M5-Button-Head-Bolt-16mm.

-

-

-

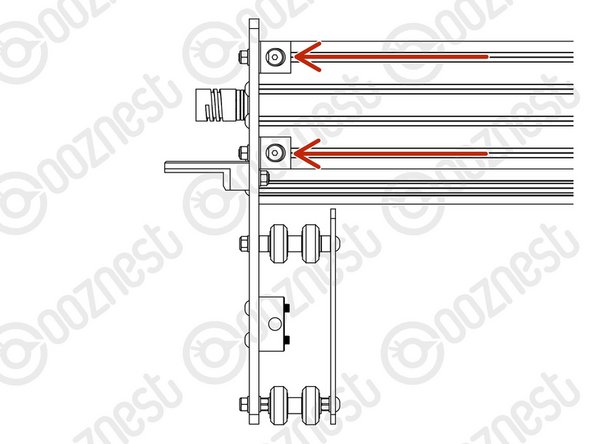

Before the Y-Carriage-Left can be attached, M5-Tee-Nuts need to be inserted.

-

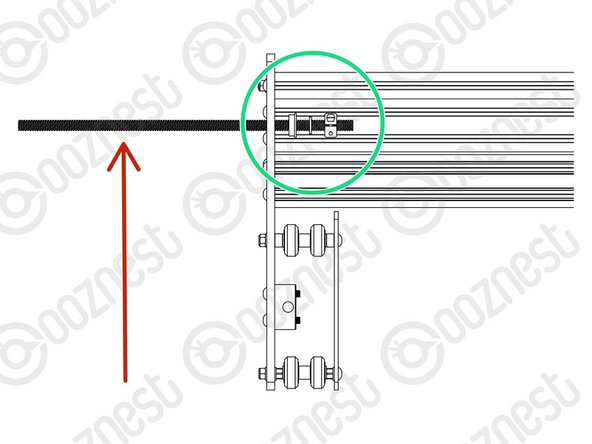

Insert 2 x M5-Tee-Nuts into the front-facing top slot of Extrusion-E.

-

Insert 2 x M5-Tee-Nuts into the front-facing bottom slot of Extrusion-E.

-

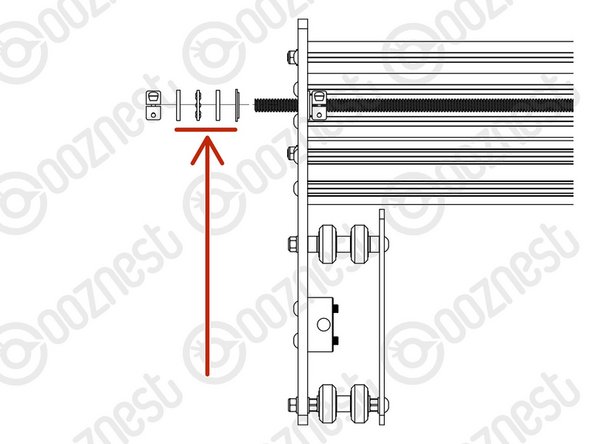

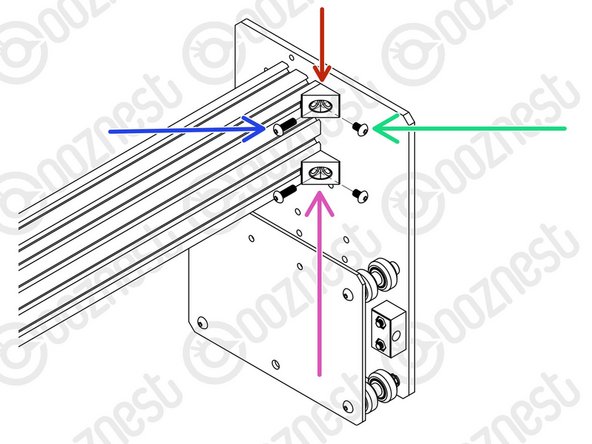

M5-Tee-Nuts going forward should always be orientated as seen in Image 3.

-

The flat face of the M5-Tee-Nut should be facing outwards.

-

-

-

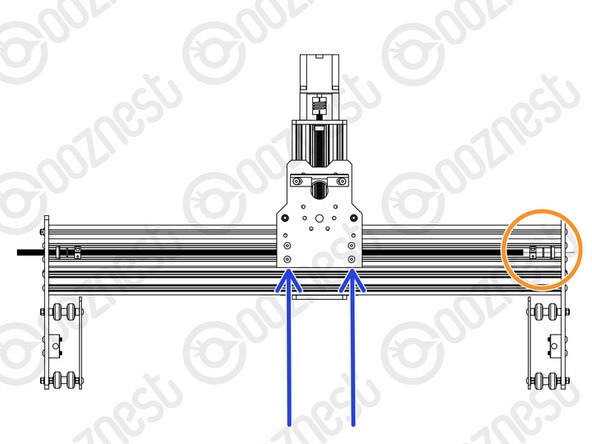

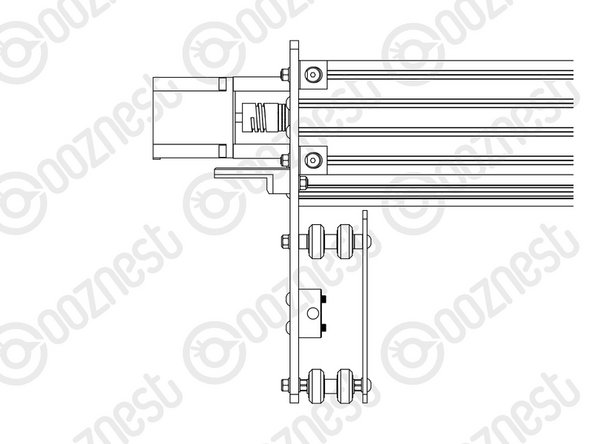

Slide the X-Carriage onto Extrusion-E in the orientation seen in Image 1.

-

Repeat Step 1 of this guide for the Y-Carriage-Left

-

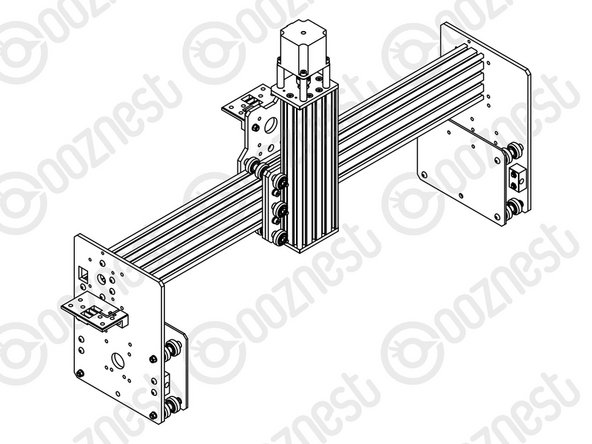

Moving forward this assembly will be known as the X-Gantry.

-

Place the X-Gantry onto a flat table and check both Y-Carriages are sitting flat on the table.

-

Loosen the bolts holding Extrusion-E/B and adjust if needed.

-

-

-

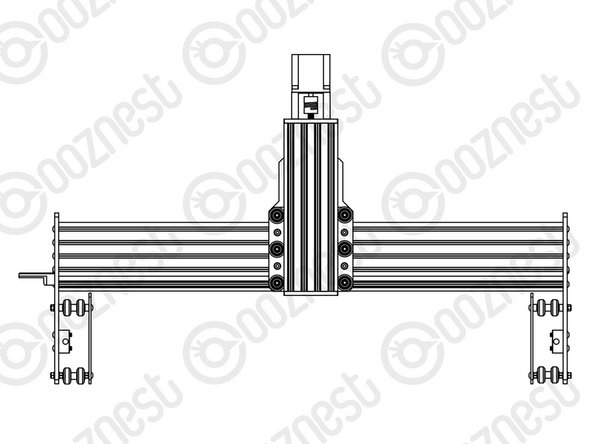

This Step and the next two Steps has the X-Gantry orientated so we are looking at the back of it. So the Y-Carriage-Right is on your lefthand side.

-

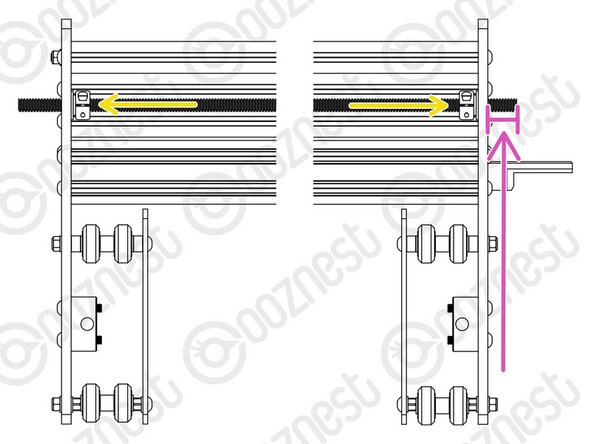

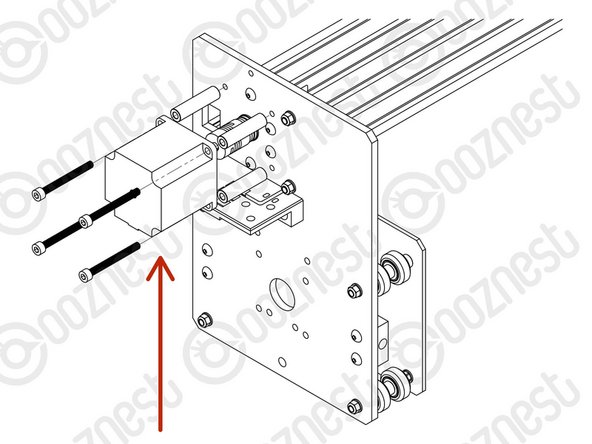

Insert the Lead-Screw-X through the large 16mm hole on the Y-Carriage-Right so it protrudes into the channel on Extrusion-E roughly 100mm.

-

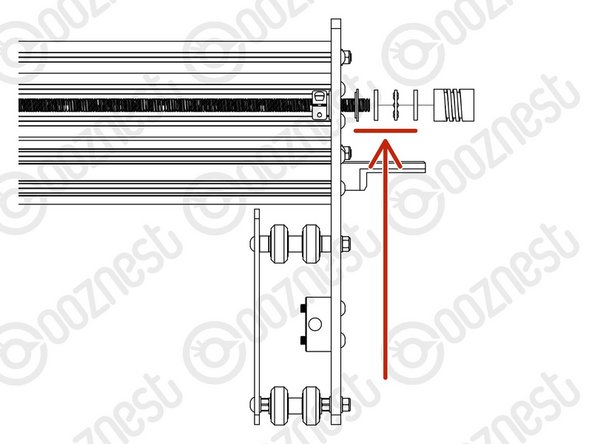

Slide onto Lead-Screw-X a Flanged-Radial-Bearing - ->- - Rubber-Bushing - ->- - Clamping-Collar.

-

Insert the Lead-Screw-X further into the channel, and then thread it through both Nut-Blocks on the X-Carriage.

-

The Nut-Blocks should be loose so their position can be adjusted to allow Lead-Screw-X to thread through.

-

Once through the Nut-Blocks, slide onto Lead-Screw-X a Clamping-Collar - ->- - Rubber-Bushing - ->- - Flanged-Radial-Bearing.

-

Thread through Lead-Screw-X further so it goes through the large 16mm hole on the Y-Carriage-Left. Adjust the Lead-Screw so there is 14mm protruding from the Y-Carriage-Left.

-

Seat the Flanged-Radial-Bearings into the Y-Carriages, slide the Rubber-Bushing against the Flanged-Radial-Bearings and finally slide the Clamping-Collars so they are against against the Rubber-Bushings. Slightly tighten the Clamping-Collars.

-

-

-

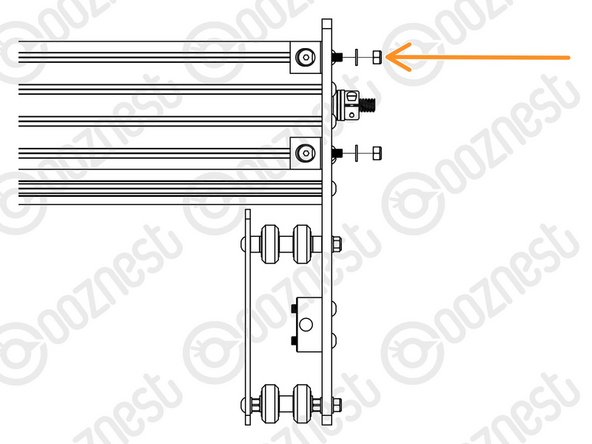

Thrust-Bearings come in 3 parts. Thrust-Bearing-Housing-Washer, Thrust-Bearing-Caged-Roller and Thrust-Bearing-Shaft-Washer

-

The Thrust-Bearing-Housing-Washer and Thrust-Bearing-Shaft-Washer look exactly the same. They are not.

-

The Thrust-Bearing-Shaft-Washer has a smaller internal diameter thus it will be tighter on the Lead-Screw.

-

We recommend adding a generous amount of bearing Lubricant to the grooved face of both washers.

-

On the Lead-Screw-X protruding from the Y-Carriage-Right (Remember it is on your left, as we are still looking from the back) slide on a Nylon-Shoulder-Washer - ->- - Thrust-Bearing-Housing-Washer - ->- - Thrust-Bearing-Caged-Roller - ->- - Thrust-Bearing-Shaft-Washer

-

The Nylon-Shoulder-Washer seats in the 16mm hole on the Y-Carriage.

-

The Thrust-Bearing-Caged-Roller seats in the grooves on the Thrust-Bearing washers. Look at Image 3 for the correction orientation of the Thrust-Bearing-Caged-Roller.

-

Finally slide on a Clamping Collar. While pushing the Clamping-Collar against the Thrust-Bearing assembly, tighten the Clamping-Collar.

-

-

-

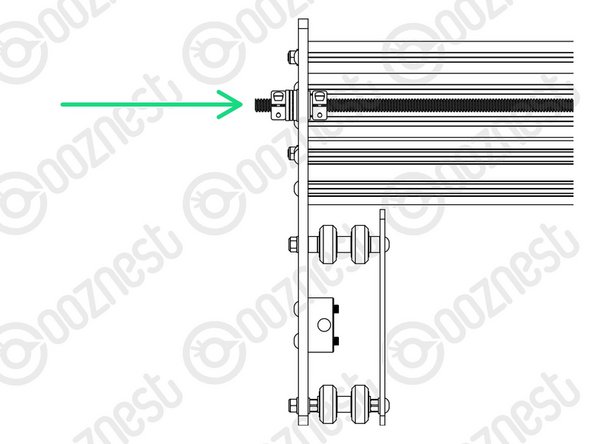

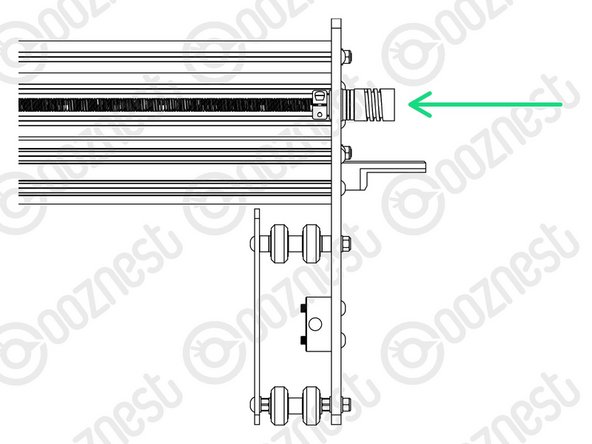

On the Lead-Screw-X protruding from the Y-Carriage-Left (Remember it is on your right, as we are still looking from the back) slide on a Nylon-Shoulder-Washer - ->- - Thrust-Bearing-Housing-Washer - ->- - Thrust-Bearing-Caged-Roller - ->- - Thrust-Bearing-Shaft-Washer

-

The Nylon-Shoulder-Washer seats in the 16mm hole on the Y-Carriage.

-

The Thrust-Bearing-Caged-Roller seats in the grooves on the Thrust-Bearing washers. Same orientation as before and going forward.

-

Finally slide on a Flexible-Coupler. While pushing the Flexible-Coupler against the Thrust-Bearing assembly, tighten Flexible-Coupler

-

On the Flexible-Coupler tighten the clamping bolt first and then the grub screw.

-

-

-

For the rest of the guide, we are now looking at the X-Gantry orientated so we are looking at the front of it.

-

An Angle-Corner goes in the corner between the Y-Carriage-Right and front-facing top slot of the Extrusion-E

-

Use a M5-Button-Head-Bolt-8mm and a previously inserted M5-Tee-Nut to attach it to Extrusion-E.

-

Insert a M5-Button-Head-Bolt-16mm through the Angle-Corner, then through the Y-Carriage.

-

Then add a Precision-Shim and M5-Nyloc-Nut on the opposite side of the Y-Carriage.

-

Repeat for an Angle-Corner between the Y-Carriage-Right and front-facing bottom slot of the Extrusion-E

-

-

-

Repeat the previous step but between the Y-Carriage-Left and Extrusion-E

-

-

-

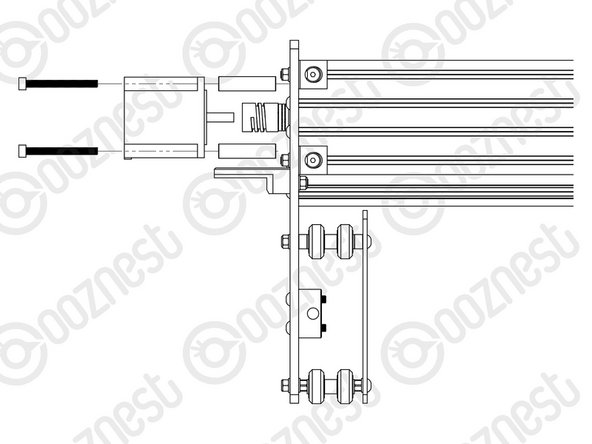

Attach a Stepper-Motor to the threaded holes on the Y-Carriage-Left using 4 x M5-Cap-Head-Bolt-50mm and 4 x Aluminium-Spacer-40mms.

-

Orient the Stepper-Motor so that the wire is facing down.

-

The shaft of the Stepper-Motor goes into the Flexible-Coupler.

-

On the Stepper-Motor side make sure the Flexible-Coupler grub screw is on the flat portion of the Stepper-Motor shaft.

-

Once in position, tighten the clamping bolt first, then the grub screw.

-

The Lead-Screw side was tightened earlier in this guide.

-

-

-

Put the X-Gantry to one side, and clear the table, you are going to need it.

-

Guide Complete - Proceed to 5. Base Assembly

-

Thanks for following the guide. Any issues, please contact us!

Thanks for following the guide. Any issues, please contact us!

Cancel: I did not complete this guide.

81 other people completed this guide.