-

-

Prepare 16 x Universal-L-Brackets with a M5-Button-Head-Bolt-8mm through each hole and a M5-Tee-Nut slightly threaded onto it.

-

The flat side of the M5-Tee-Nut should be facing the Universal-L-Bracket.

-

-

-

With a Universal-L-Bracket in hand take note that the holes down one side are closer to the corner of the Universal-L-Bracket than the other side.

-

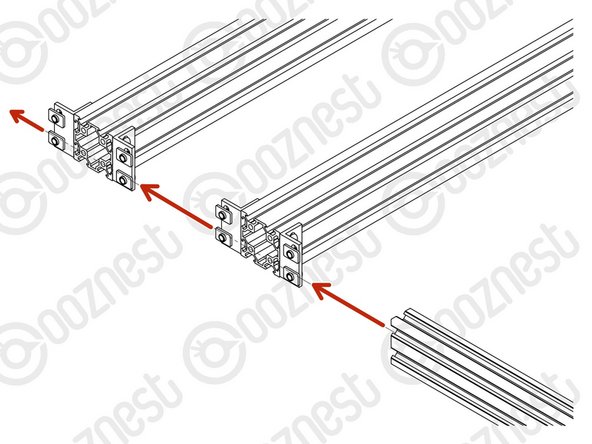

Slide the side of the Universal-L-Bracket with the holes closest to the corner onto one end of an Extrusion-C.

-

Align the Universal-L-Bracket flush with the end of Extrusion-C and tighten the M5-Button-Head-Bolts-8mm.

-

Repeat for the other 3 corners of the Extrusion-C.

-

Repeat all points above for the other 3 Extrusion-C's.

-

-

-

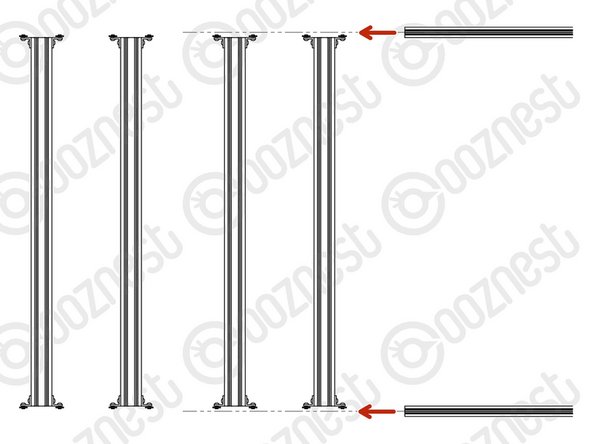

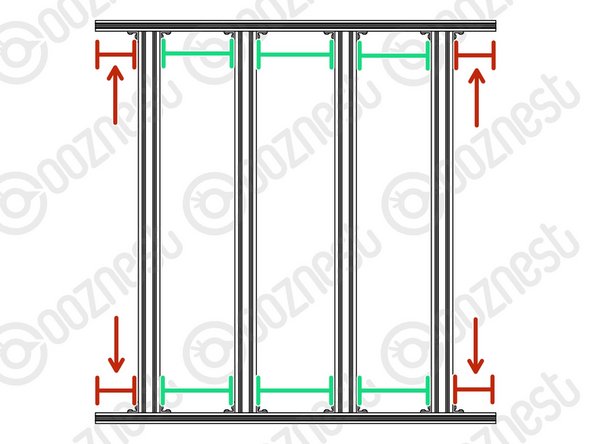

Lay all Extrusion-C's out on a flat table with the ends roughly flush with each other as in Image 1.

-

Front and Back, slide a Extrusion-A through all the Tee-Nuts on each Extrusion-C.

-

Roughly evenly space the Extrusion-C's along the Extrusion-A's.

-

Keep them loose, they will be adjusted in the next Step.

-

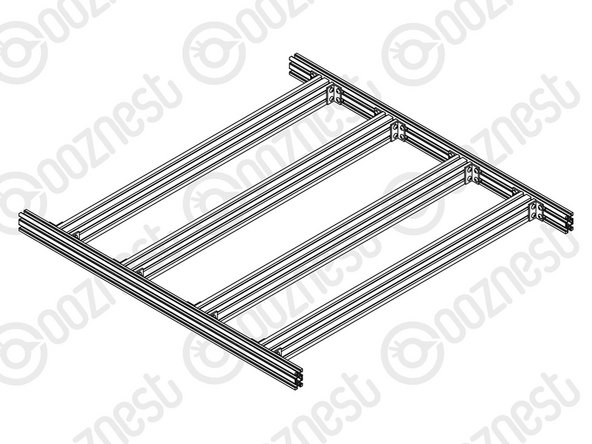

You should end up with something that looks similar to Image 3.

-

-

-

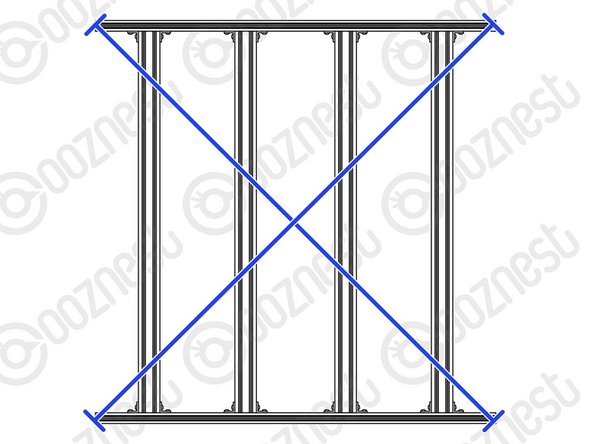

It is important that you carry out the below on a perfectly flat surface.

-

While doing the below, you will need an engineers square.

-

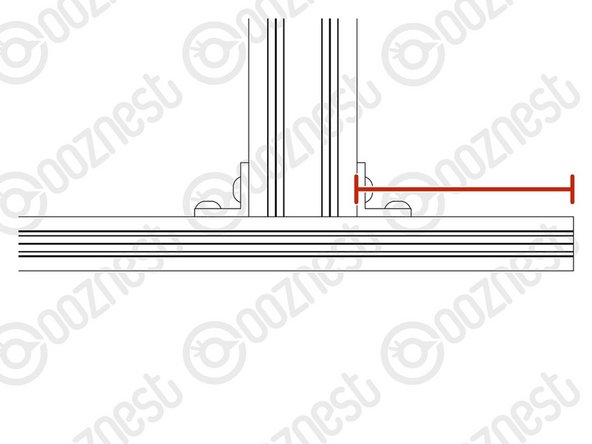

The two outside Extrusion-C's should be spaced 80mm in from the end of the Extrusion-A's.

-

Once in position, check they are square with the Extrusion-A's, then tighten all the M5-Button-Head-Bolt-8mm on these two Extrusion-C's.

-

The central two Extrusion-C's should be spaced evenly so the 3 gaps are of equal size.

-

Once in position, check they are square with the Extrusion-A's, then tighten all the M5-Button-Head-Bolt-8mm on these two Extrusion-C's.

-

To double-check the base is square, measure the diagonals. They should be the same.

-

Adjust if needed.

-

-

-

You are getting to see the scale of it now. Keep the Base-Assembly on the table ready for the next guide.

-

Guide Complete - Proceed to 6. Y-Gantry Assembly

-

Thanks for following the guide. Any issues, please contact us!

Thanks for following the guide. Any issues, please contact us!

Cancel: I did not complete this guide.

76 other people completed this guide.