-

-

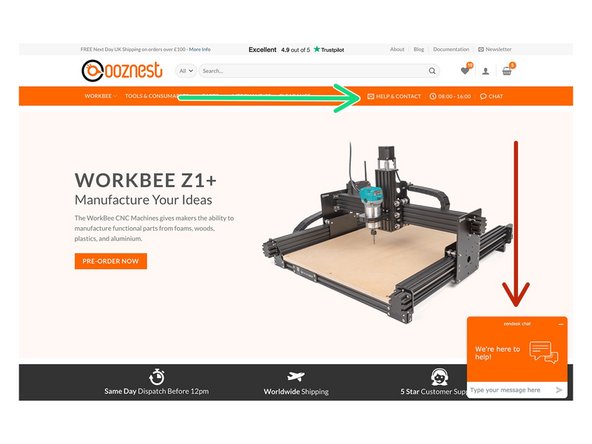

The manual is broken down into sections: Mechanical Assembly, Electronics Assembly, Connecting and Testing.

-

Connecting is broken into two sub sections - Connect Via Wifi and Connect Via Ethernet.

-

Only follow the sub section matching the connectivity of your machine.

-

For the Ethernet version, you do not need to connect via USB.

-

Within each section follow through the guides in numerical order.

-

-

-

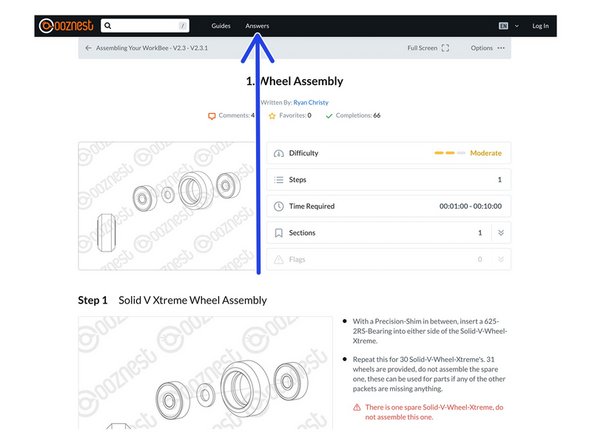

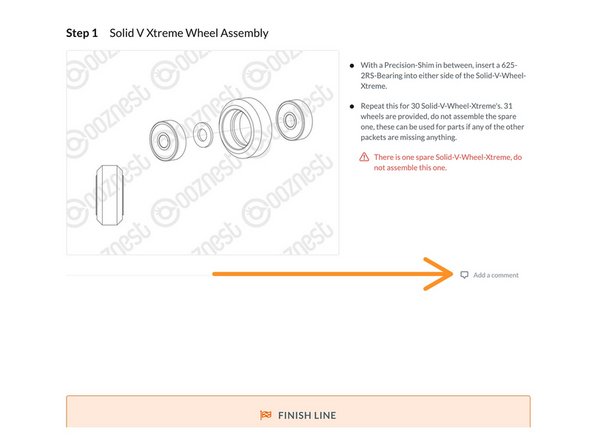

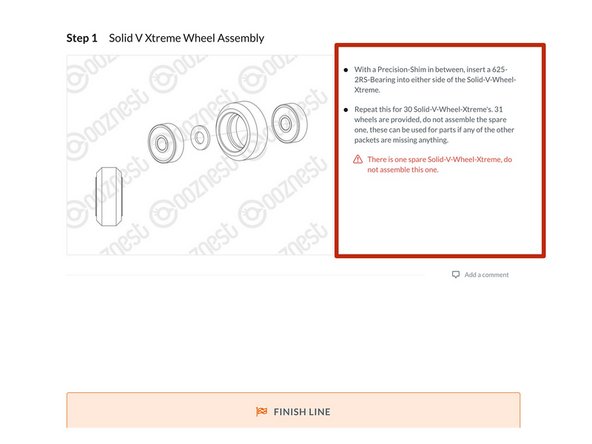

Each Guide is broken down into a number of Steps.

-

Each Step is broken down into a number of coloured Points.

-

Complete all Points in each Step, and all Steps in each Guide to complete the Guide.

-

Some Steps/Points may not apply to your version. It will be clearly indicated to which version they apply.

-

Each Step will have one or more image.

-

Click on the image to view the high resolution version.

-

Try it now!

-

Go to 'Options' > 'Download PDF' to get a printable version of each guide.

-

-

-

1.5, 2.0, 2.5, 3.0, 4.0, 5.0mm Hex keys

-

5.5, 7.0, 8.0mm Spanners

-

Selection of Philips and Flathead Screwdrivers. Pozi #1 & Pozi #2 required. Insulated versions should be used on electronics

-

Engineers Square

-

Soft mallet or Rubber hammer

-

Tweezers and Wire cutters

-

A bearing lubricant such as SuperLube Grease

-

Do not use power tools to assemble the WorkBee Z1+

-

-

-

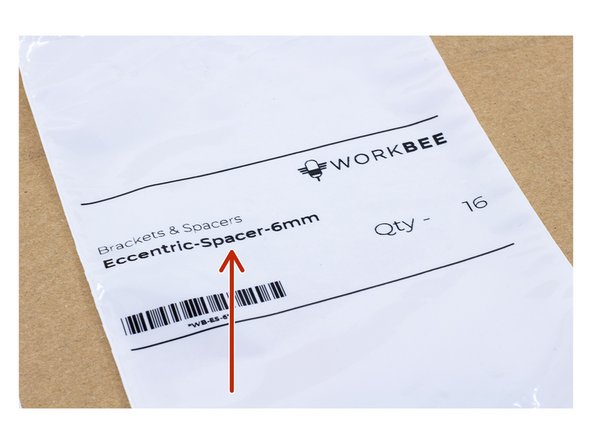

Most parts of the kit are labelled with the part name and quantity provided.

-

The name on the label will match the name used in the guides.

-

For most small parts we will provide spares.

-

The quantity on the label will include any spares.

-

To quickly find which parts are in which box Download and print our Box Cheat Sheet

-

-

-

Each Extrusion or Lead-Screw is assigned a letter.

-

In the Guide these will be referred to as Extrusion-A, Extrusion-B, Lead-Screw-Z etc

-

Extrusion-F and Lead-Screw-Y are matched pairs. Do not mix these with other Extrusions or Lead-Screws

-

We recommend that the labels are not removed until the build is complete, as the guides will refer to these letters throughout.

-

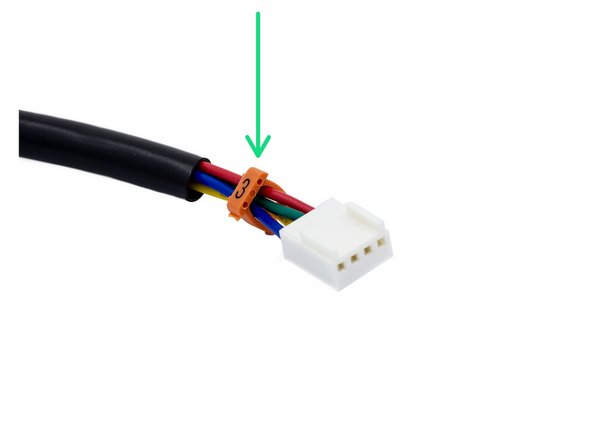

The wires coming from each Motor or Limit Switch will be assigned a Number & Colour based on the Axis they are used for.

-

In the guides, these will be referred to as Limit-Switch-0, Motor-Wire-3, Motor-Wire-4 etc

-

Download and print our Motor Wire and Limit Switch Cheat Sheet

-

-

-

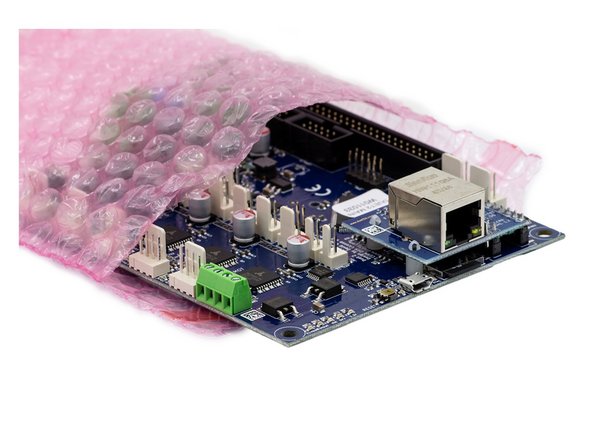

Electronic Boards will come in an ESD Bag.

-

Do not take the Electronic boards out of the bag until needed.

-

Touch something metal before touching the board to discharge any static electricity.

-

Never touch the components on the board. Always handle the board via the edges.

-

Be extra cautious when you are around static materials, such as carpets and wool.

-

-

-

If you are using a USB to Ethernet adaptor it must have crossover detection.

-

Not all USB to Ethernet adaptors have this feature. So double check your model.

-

We sell a tested USB to Ethernet Adaptor on our Website

-

-

-

Read each guide from start to finish before beginning. This will give you an idea of the direction you are heading.

-

Don't just look at the pictures. The written instructions are as concise and cleary written as possible.

-

Follow these guides only! Do not follow other WorkBee build guides or YouTube videos. Do not even follow Ooznest's videos. They may not apply to your version.

-

Everything should go together easily. If something is requiring a lot of force. Take a breather and read the guides again.

-

M5-Tee-Nuts have to be inserted from the end of the extrusion. If you forget to insert one don't panic!

-

Spare M5-Drop-In-Tee-Nuts are provided. Simply drop them in the slot, engage the bolt, and they will bite into the underside of the slot.

-

Don't Rush! Building the WorkBee is as much fun as using it. The quicker you build it the less fun you will have :)

-

You are ready to begin! Start with 1. Wheel Assembly

-

Cancel: I did not complete this guide.

84 other people completed this guide.

4 Comments

Hi I am considering purchasing one of your cnc machines in the near future.I already have a small Dewalt router would this fit to your router mount okay ?…..thanks.

Geoffrey Wilson - Resolved on Release Reply

Hi Geoffrey,

Great to hear you are interested in our machine!

What model is it? If it is a D26200, then it will fit.

Thanks!

Robert -

1mm hex key? The smallest metric size I believe is 1.5mm, then there some weird sizes like 1.3 and 0.9. I have searched my usual tool suppliers but none have 1mm hex keys. So I hope you have some suggestion as to where I could purchase this before I start my build.

Xander Langschmidt - Resolved on Release Reply

Hello Xander, Thanks for spotting this!

I have updated the guide it should be 1.5mm the smallest needed for the flexible coupler grub screws.