-

-

If the wires in your kit have white printed tags, please ignore this step. Each wire, at the connector end has a coloured clip with a number. This colour and number identifies this wire. Please see key below.

-

(0)(Black) X-Axis Limit Switch

-

(1)(Brown) Y-Axis Limit Switch

-

(2)(Red) Z-Axis Limit Switch

-

(3)(Orange) X-Axis Stepper Motor Wire.

-

(4)(Yellow) Left Y-Axis Stepper Motor Wire.

-

(5)(Green) Right Y-Axis Stepper Motor Wire.

-

(6)(Light Blue) Z-Axis Stepper Motor Wire.

-

-

-

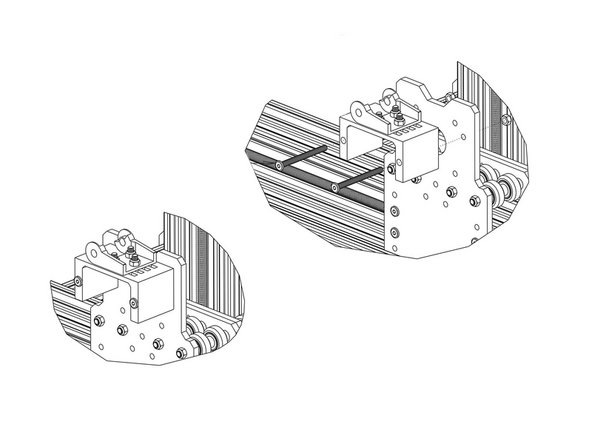

Attach a Drag-Chain-Fixed-End to the V-Slot-2040-750mm using an M5-Low-Profile 8mm and an M5-Drop-In-Tee-Nut.

-

It should be located 150mm from right hand end of the V-Slot-2040-750mm if looking from the back. Ensure that it is parallel with the V-Slot-2040-750mm.

-

-

-

WorkBee Kits may include different version drag chains, please refer to the correct drawings for assembly of the version supplied.

-

Attach a Drag-Chain-Moving-End to the X-Drag-Chain-Moving-End-Mount in the orientation shown above using 3 x M5-Low-Profile-15mm bolts and 3 x M5-Nyloc-Nuts.

-

Attach a Drag-Chain-Moving-End to the X-Drag-Chain-Moving-End-Mount in the orientation shown above using 2 x M5-Low-Profile-15mm bolts and 2 x M5-Nyloc-Nuts.

-

-

-

--- WorkBee 2.2.1 ---

-

Secure the X-Axis-Moving-End-Assembly to the X-Plate-Back using 2 x M5-Low-Profile-60mm bolts and 2 x M5-Nyloc-Nuts.

-

--- WorkBee 2.2 ---

-

Secure the X-Axis-Moving-End-Assembly to the X-Plate-Back using 2 x M5-Low-Profile-55mm bolts and 2 x M5-Nyloc-Nuts.

-

-

-

Like with the Y-Axis, lay the X-Drag-Chain flat on a table. Feed through the (6)(Light Blue) Z-Axis Stepper Motor Wire.

-

If you have an Ooznest XYZ Touch Probe, please complete Step 4 of Assembling Your Original WorkBee XYZ Touch Probe

-

The tabs of the Drag-Chain can be flipped open with a small flathead screwdriver. Doing this will help to feed the cables.

-

The end of the stepper motor wires with the black connectors should be at the male end of the X-Drag-Chain (opposite to Y-Axis).

-

Attach the female end of the X-Drag-Chain to the Drag-Chain-Fixed-End on the V Slot-2040-750mm. It will take some force to click it into the Drag-Chain-Fixed-End. A small flathead screwdriver can be used to help pry the Drag-Chain in place.

-

Bring the male end of the X-Drag-Chain up to the X-Axis-Moving-End-Assembly and attach it to the Drag-Chain-Moving-End. It will take some force to click it into the Drag-Chain-Moving-End. A small flathead screwdriver can be used to help pry the Drag-Chain in place.

If you’ve followed the steps accurately your router would have been installed. So you can route the power cable at the same time.

Craig McAteer - Resolved on Release Reply

I found that connecting the drag chains to the moving-end and fixed-end assemblies quite difficult when they were in place and was concerned that I might break them.

It was far easier to connect them first and then attach the assemblies to the frames.

Mike Darlow - Resolved on Release Reply

-

Thanks for following the guide. Any issues, please contact us!

Thanks for following the guide. Any issues, please contact us!

Cancel: I did not complete this guide.

25 other people completed this guide.

2 Comments

Reference to the installation of the touch probe should be mentioned just after feeding the motor cable… Thanks

Andre Ravary - Resolved on Release Reply