Introduction

Please read before proceeding to avoid damaging the controller and voiding your warranty

- Avoid connecting the Duet via USB when you do not need to. (Except when instructed to in the guides)

- Always unplug the WorkBee Power Supply before connecting the USB Cable.

-

-

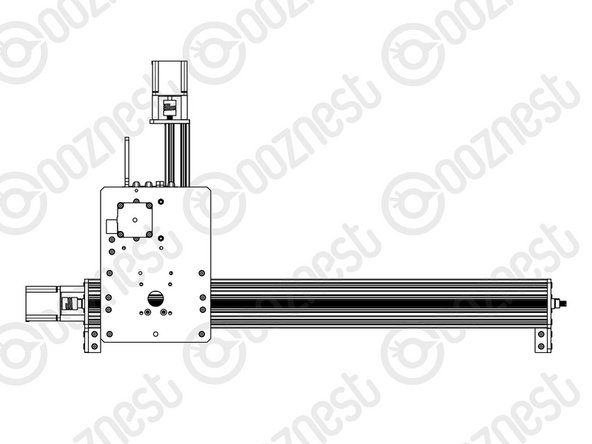

If looking at the machine from the front the correct axis motion is, X-Axis is positive towards the right.

-

The Y-Axis is positive going away.

-

The Z-Axis is positive going up.

-

-

-

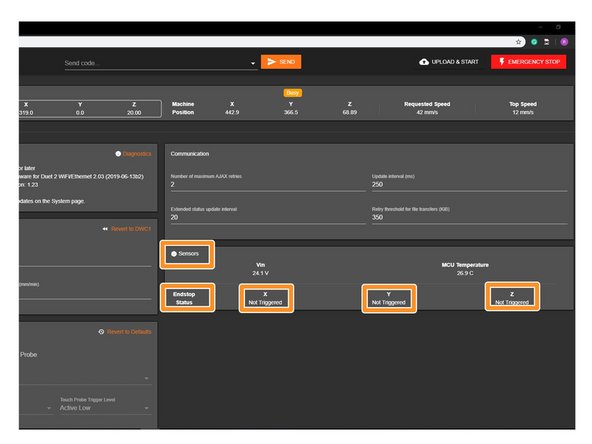

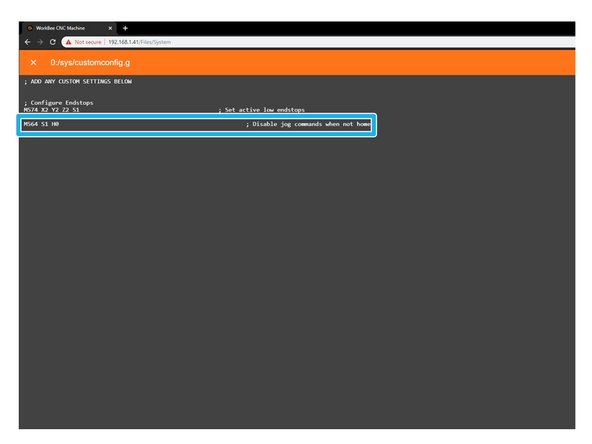

In WorkBee Control, under Settings > Machine-Specific > Sensors, take note of the Vin number. It needs to read 24.0V. If it does not read 24.0V, please follow the steps below.

-

Using an insulated Phillips Screw Driver adjust the Power Supply output voltage by rotating the white plastic screw inside the Ooznest Logo.

-

Adjust the output voltage so it reads 24.0

-

-

-

In WorkBee Web Control under to Settings > Machine Specific > Sensors, you will find the statuses of the limit switches.

-

Activate the X-Axis limit switch with your finger. Hold for a few seconds.

-

The endstop status should change to 'Triggered'

-

It is normal for there to be a delay between pressing the limit switch and the status being updated. Please do not be concerned, the board will stop the motor instantaneously.

-

Repeat this procedure for the Y & Z Limit switches.

-

If any do not behave as intended do not proceed with this guide, please contact us: https://ooznest.co.uk/help/

-

-

-

If any of the limit switches did not behave as intended in the previous step, do not proceed with this step & guide, please contact us: https://ooznest.co.uk/help/

-

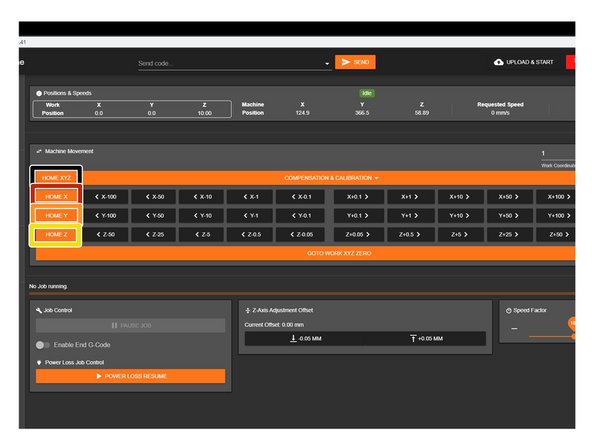

When the machine homes, it will raise the Z-Axis, and then move the X and Y-Axis to the far right-hand corner.

-

If any of the points below do not behave as explained, do not proceed with this guide, please contact us: https://ooznest.co.uk/help/

-

Press Home Z. The Z-Axis should raise upwards, bounce once on the limit switch, and then stop.

-

Press Home X. The Z-Axis should home like the previous. The X-Axis should then move towards the right, bounce once on the limit switch, and then stop.

-

Press Home Y. The Z-Axis should home like previous. The Y-Axis should then move towards the back, bounce once on the limit switch, and then stop.

-

Press Home All. The Z-Axis should home like previous. Then the X and Y-Axis should home like previous.

-

-

-

Re-home the machine so the machine is at the maximum on all axes.

-

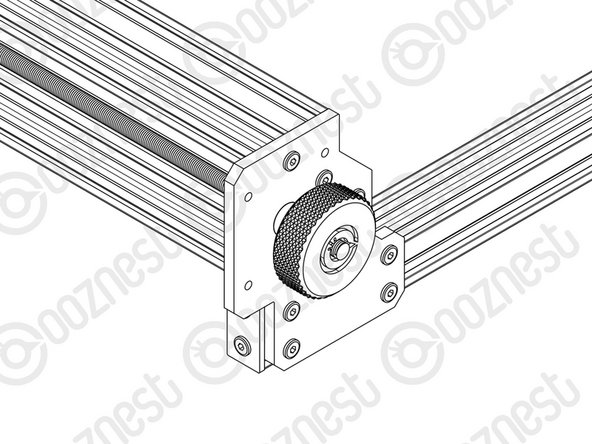

On the Left Hand Y-Axis ACME Screw , if looking from the front, thread the Tensioning-Knob onto the end of the ACME Screw.

-

Loosen the 8mm-Clamping-Collar.

-

Turn the Tensioning-Knob clockwise, you will feel the screw tension, turn it until the motor clicks over.

-

Just before this point where the motor clicks, is the correct tension for the ACME Screw. While holding the tensioning knob at this point, push the 8mm-Clamping-Collar against the 8mm-Shim and F688ZZ-Bearing and tighten the 8mm-Clamping-Collar.

-

Remove the Tensioning-Knob.

-

Repeat for the Right Hand Y-Axis Screw.

-

To tension the X-Axis screw jog the machine furthest left and repeat the above steps to tension correctly.

-

-

-

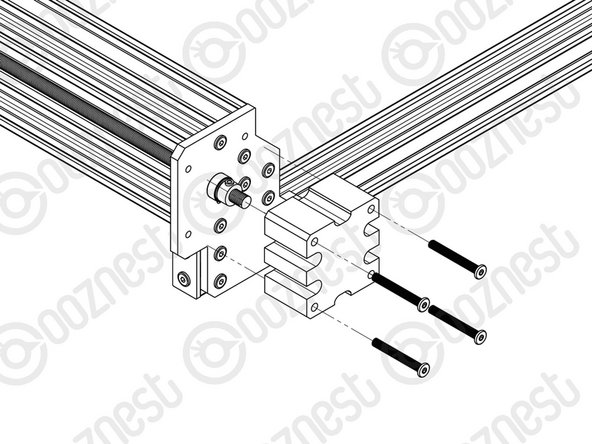

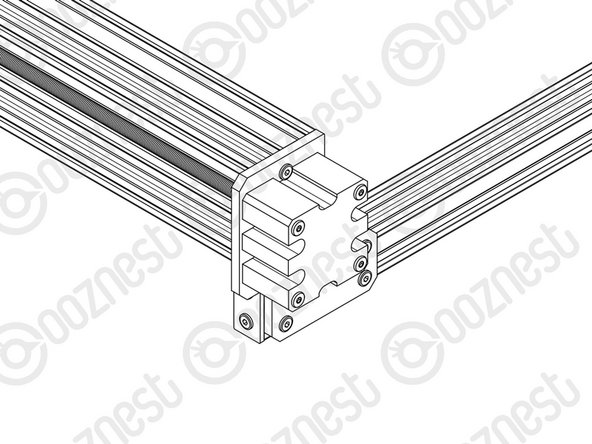

Onto the end of each ACME Screw attach an ACME-End-Cap using 4 x M5-Low-Profile-40mm bolts.

-

-

-

Congratulations you have completed the assembly and testing of your Ooznest Original WorkBee CNC Machine.

-

We recommend following these two guides to learn how to use your WorkBee: WorkBee Control Overview & How To Set up a Job on the WorkBee CNC Machine

-

Thanks for following the guide. Testing of the WorkBee is now complete!

Thanks for following the guide. Testing of the WorkBee is now complete!

Cancel: I did not complete this guide.

17 other people completed this guide.