-

-

To complete this guide you will need a 250x250x18mm piece of MDF.

-

Use 4 x Wood Screws to secure the MDF to the Spoilerboard.

-

Make sure it is square with the machine.

-

Make sure the Wood Screws are flush with the surface of the MDF.

-

-

-

Always use the correct collet size for the cutter.

-

Mafell

-

Click the collet into the nut first, then insert the end mill fully.

-

Fix the collet with a maximum torque of 10-11Nm. Tighten the collet by hand, then a 1/8 turn with a spanner, this should be about right.

-

Keep the collet lubricated with a solid lubricant (e.g. Molykote P-40) or by lightly greasing.

-

Katsu

-

Push the collet into the shaft and then the nut over it. The end mill can then be inserted fully.

-

Only use the button on the side to hand tighten the collet. To fully tighten, use two spanners, a 13 spanner on the flat portion of the shaft, the included 22mm spanner on the collet nut.

-

-

-

Turn off and unplug the Router Head from the mains.

-

Inside the Extras Box find the 1/4" Square Cut End mill.

-

Using a 1/4" collet secure the end mill to the Router Head.

-

The Mafell has a locking button on the side.

-

The Katsu requires a 13mm Spanner and the included 22mm Spanner.

-

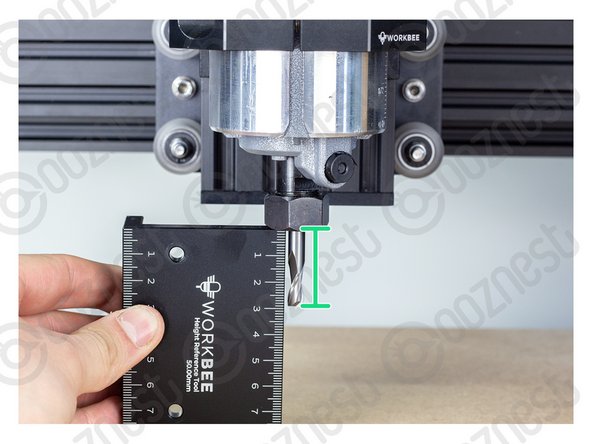

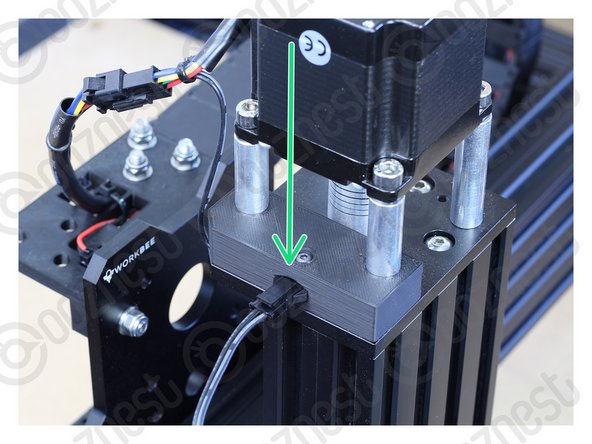

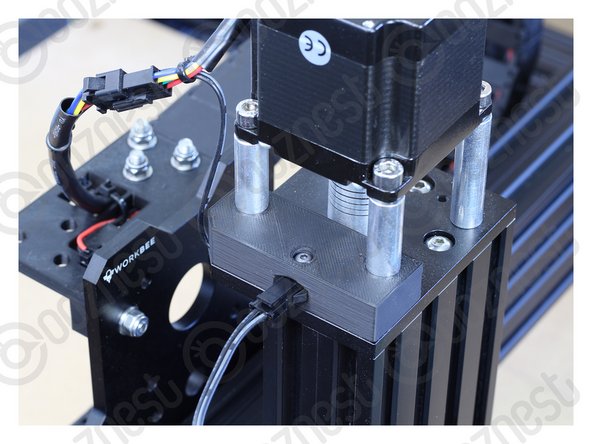

While tightening, set the end mill stick out to 30mm using the Height-Reference-Tool.

-

-

-

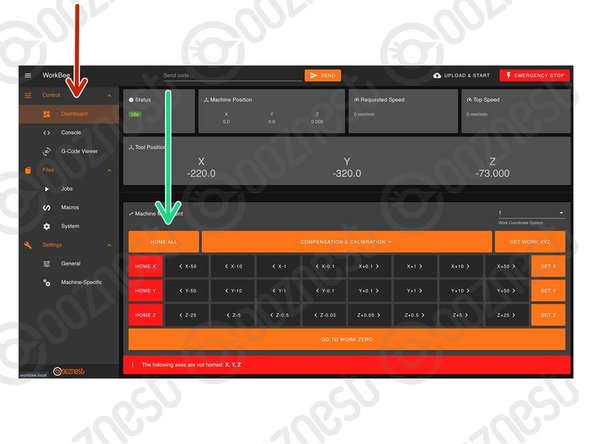

Turn on the machine and open WorkBee Control.

-

Go to Control > Dashboard

-

Press 'Home All'

-

The Machine should now be at the back-right corner of the work area.

-

-

-

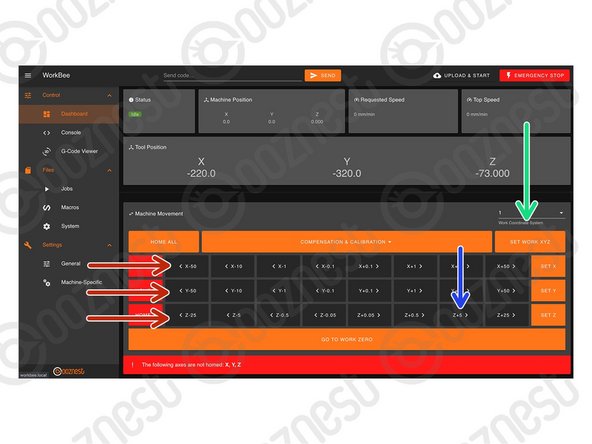

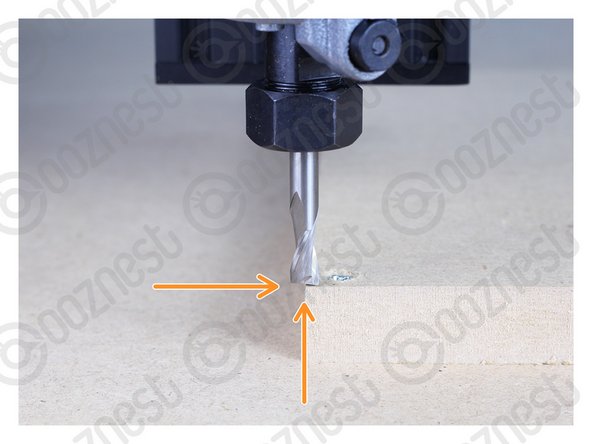

Use the job buttons to centre the end mill over the front left corner of the MDF.

-

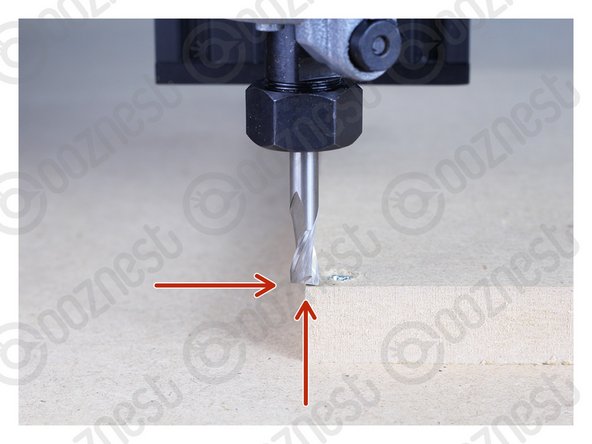

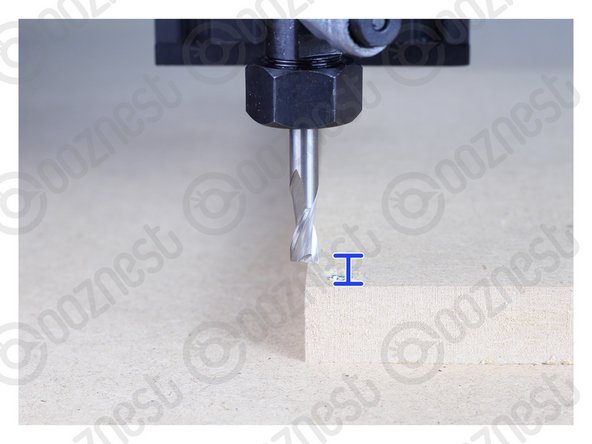

The tip of the end mill should be flush with the top of the MDF.

-

Press 'Set Work XYZ' to set the work zero position.

-

Jog the Z-Axis up +5mm.

-

-

-

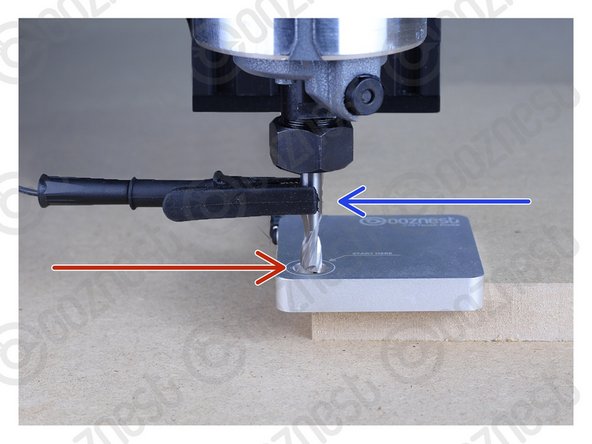

Locate your Touch Probe over the corner of the MDF.

-

Use the job buttons to centre the end mill in the 'Start Here' Hole.

-

With the tip of the endmill roughly level with the surface of the Touch Probe.

-

Plug your Touch Probe into the Touch Probe Mount Connector.

-

Clip the Crocodile Clip to the End mill.

-

-

-

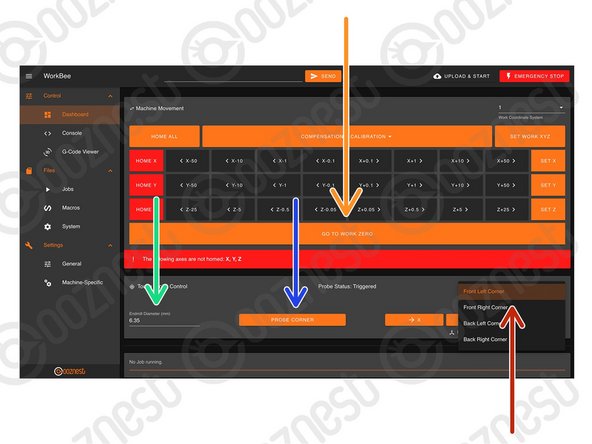

In the 'Touch Probe Panel' Select the Front Left Corner as the Probe Location.

-

Define the Endmill Diameter as 6.35mm

-

Press Probe Corner to begin probing.

-

Wait until the 'Probe Successful' confirmation.

-

Do not press any 'Set Work Zero' buttons after this.

-

Unclip the Touch Probe from the End mill and unplug it from Touch Probe Mount. Remove the Touch Probe.

-

Press 'Go to Work Zero'. Your machine should be perfectly aligned with the corner of the material.

-

Jog the Z-Axis up +5mm.

-

-

-

Download the WorkBee-First-Project file and extract the contents.

-

-

-

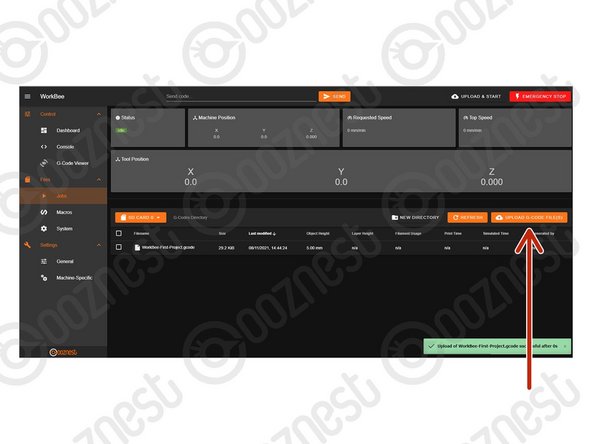

Go to File Management > Jobs and press 'Upload G-Code Files'

-

Navigate to where you extracted the download.

-

Select 'WorkBee-First-Project.gcode'

-

-

-

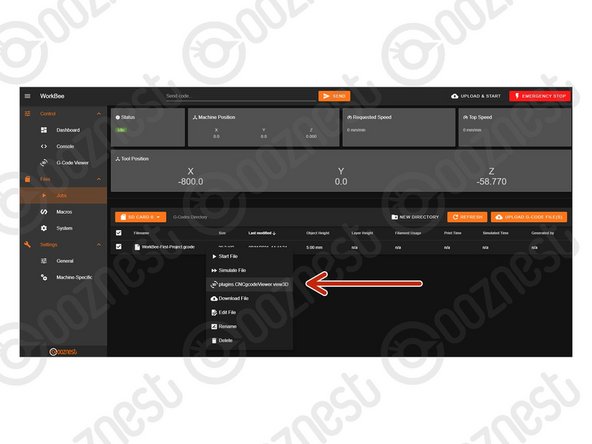

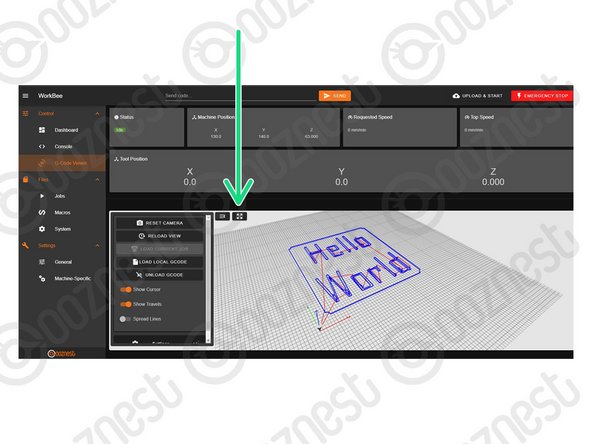

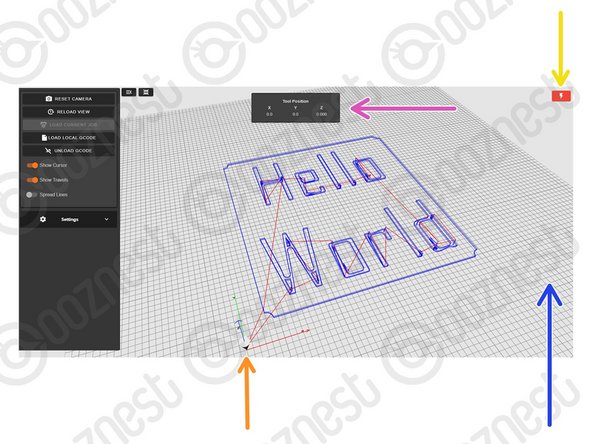

Right click the file under File Management > Jobs and press 'plugins.CNCgcodeViewer.view3D'

-

Go to Control > G-Code Viewer and view it fullscreen.

-

The grid shows the machines working area.

-

The X, Y, and Z-Axis markers show where the selected Work Zero is located in the machines working area.

-

Current position in Work Coordinates.

-

Software emergency stop.

-

If you press 'Unload G-Code' and reload it as above once the job is running, it will show the current progress in green.

-

-

-

Mafell

-

Set the thumbwheel on the Router Head to Number 6 (25000 RPM)

-

WorkBee Router Head

-

WorkBee Router Head/Katsu

-

Set the thumbwheel on the Router Head to Number 4 (25000 RPM)

-

-

-

Adjust the height of the Dust Shoe so the tip of the brushes are just touching the MDF piece we are cutting.

-

Fix into position using the clamping bolt on the side of the Dust Shoe.

-

-

-

The MDF is secure.

-

The Work Zero is Set.

-

The Work Area is clear.

-

The End Mill is secure.

-

Safety Instructions Read.

-

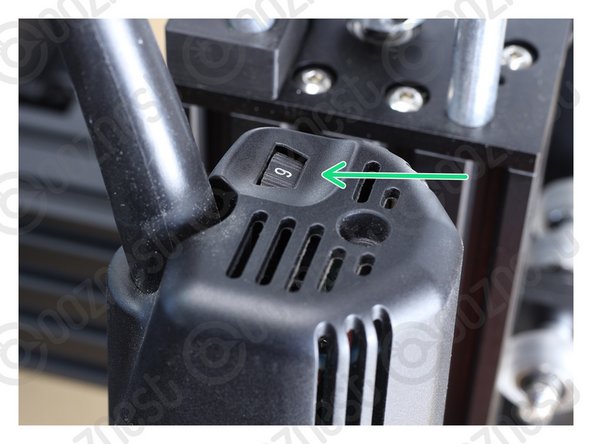

Switch on the Router Head.

-

Switch on your Extractor (If applicable).

-

-

-

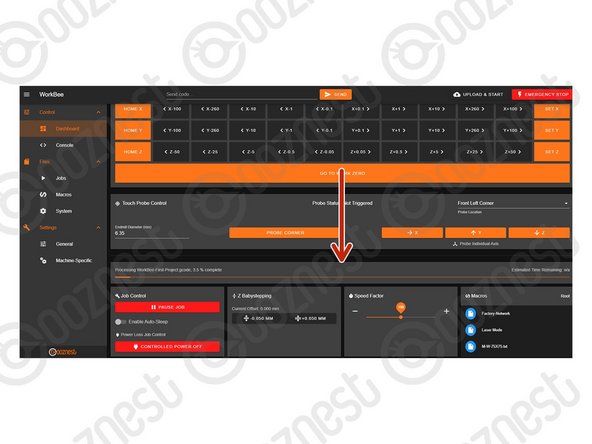

Go to Files > Jobs

-

Press on the WorkBee-First-Project.gcode File.

-

Press 'Yes' to start.

-

-

-

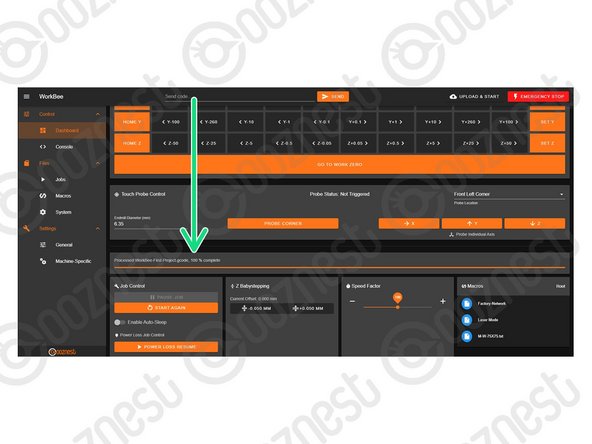

When running a job, the progress of the job will be displayed here along with the percentage complete and estimated time remaining.

-

Wait for the Job to be 100% Complete and the machine has stopped moving.

-

Switch off the Router Head.

-

Switch off your Extractor (If applicable).

-

Press 'Home All'

-

-

-

Unscrew the Project.

-

-

-

Congratulations you have finished your First Project on the Original WorkBee Z1+ CNC Machine.

-

Share your project on Instagram tag @Ooznest and use #WorkBee

-

-

-

Completing your First Project was rewarding right?

-

Now you can learn how to create projects using CAM Software.

-

Vectric - The Basics

-

Carveco - Tutorial Projects

-

Learn more about WorkBee Control

-

Thanks for following the guide. Any issues, please contact us!

Thanks for following the guide. Any issues, please contact us!

Cancel: I did not complete this guide.

13 other people completed this guide.