-

-

You are going to need our Motor Wire and Limit Switch Cheat Sheet. We recommend printing it off!

-

-

-

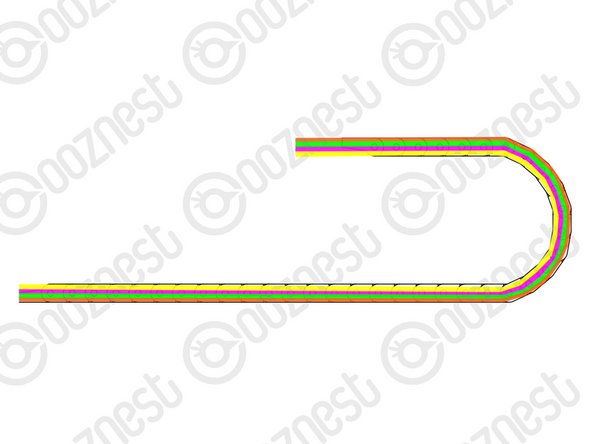

Look at the X & Y Drag-Chains.

-

On each end, there is an end mount.

-

If the end mount connects to the next link on the outside, this is known as the Moving End.

-

If the end mount connects to the next link on the inside, this is known as the Fixed End.

-

It is important you remember this, as these terms will be used going forward.

-

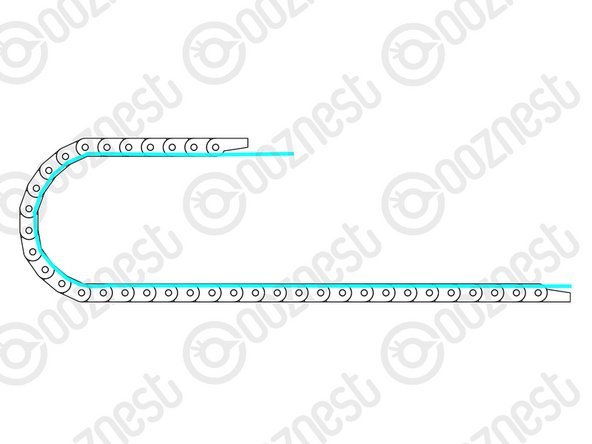

Take a look at the links of the Drag-Chains. On one side of each link, there is a little slot.

-

If you put a Flathead Screwdriver in this slot and twist. The top tab of the Drag-Chain will open.

-

Knowing this can come in useful later!

-

-

-

Lay the Drag-Chain-Y flat out on a table.

-

Feed through Limit-Switch-1.

-

The switch end of Limit-Switch-1 should be at the Fixed End of Drag-Chain-Y

-

Feed through the output cable of the Emergency-Stop.

-

The red/black crimped connectors should be at the Moving End of Drag-Chain-Y.

-

Feed through Motor-Wire-4 and Motor-Wire-5.

-

The black connector of the Motor-Wires should be at the Fixed End of Drag-Chain-Y.

-

If you have the Ethernet version of the machine. Feed through the Ethernet Cable. (Orientation does not matter)

-

-

-

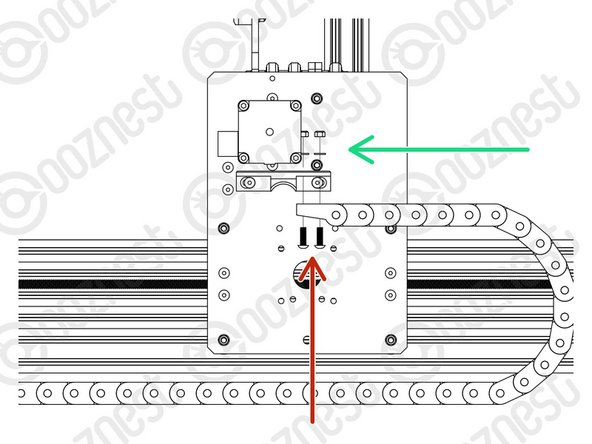

Position Drag-Chain-Y flat along the left side of the machine.

-

The Fixed End of Drag-Chain-Y should be at the back of the machine.

-

The Fixed End of Drag-Chain-Y will be fixed into position in a later guide.

-

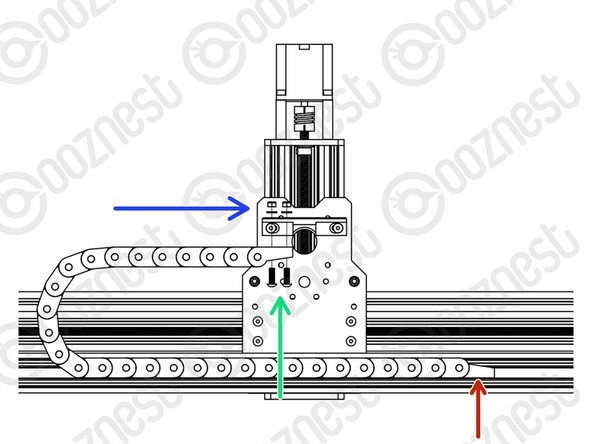

Bring the Moving End of Drag-Chain-Y upwards to the Drag-Chain-Mount on the Y-Carriage-Left.

-

Attach it to the 3 holes on the Drag-Chain-Mount using 3 x M5-Button-Head-Bolt-16mm through the bottom.

-

The add 3 x Precision-Shims and 3 x M5-Nyloc-Nuts on the opposite side of the Drag-Chain-Mount.

-

-

-

Lay the Drag-Chain-X flat out on a table.

-

Feed through Motor-Wire-6

-

The black connector of Motor-Wire-6 should be at the Moving End of Drag-Chain-X.

-

-

-

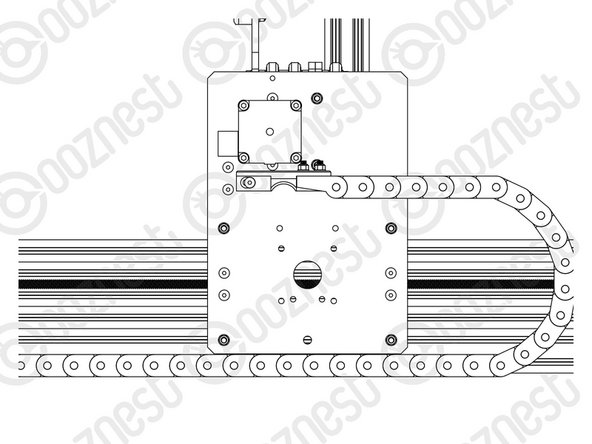

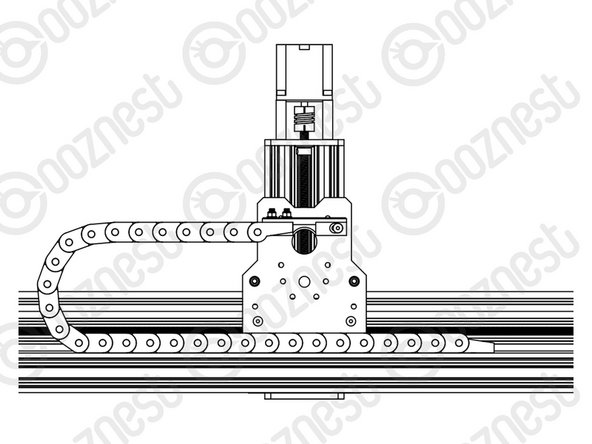

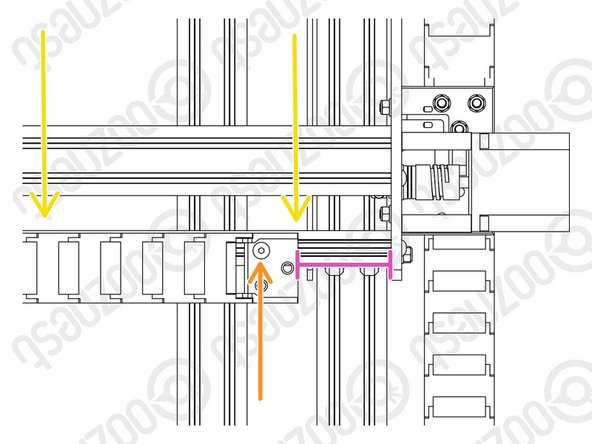

Position Drag-Chain-X flat along the back of the X-Gantry sitting on top of Extrusion-B.

-

If looking from the back, the Fixed End of Drag-Chain-X should be at the right side of the machine.

-

Bring the Moving End of Drag-Chain-X upwards to the Drag-Chain-Mount on the X-Carriage.

-

Attach it to the 3 holes on the Drag-Chain-Mount using 3 x M5-Button-Head-Bolt-16mm through the bottom.

-

The add 3 x Precision-Shims and 3 x M5-Nyloc-Nuts on the opposite side of the Drag-Chain-Mount.

-

Attach the Fixed-End of Drag-Chain-X to Extrusion-B using 1 x M5-Button-Head-Bolt-8mm and a M5-Drop-In-Tee-Nut.

-

There should be a 90mm gap between the end of Drag-Chain-X and the inside of the Y-Carriage. You can reduce this distance once you start using the machine to stop Drag-Chain-X from hitting the Y-Carriage at the opposite end.

-

Drag-Chain-X should run flush with Extrusion-B.

-

-

-

Don't worry we will tidy up all the messy wires!

-

Guide Complete - Proceed to 2. Limit Switches

-

Thanks for following the guide. Any issues, please contact us!

Thanks for following the guide. Any issues, please contact us!

Cancel: I did not complete this guide.

62 other people completed this guide.

10 Comments

Hi Ryan, on Step 4, I had to swap an M5x16 bolt for an M5x12 bolt to avoid a foul with one of the Stepper Motor spacers.

Ian Martin - Resolved on Release Reply

Hi Ian,

Thanks for your feedback. That is strange, on our machine here it misses it by 1mm. I think there is some movement on the spacer to sit slightly higher. Robert

Robert -

I have a problem where the Drag-Chain-X is too long (so collides at 90mm offset etc) and my Limit switch-2 which runs inside is too short and only just protrudes?

Mark Stone - Resolved on Release Reply

Hi Mark,

Thanks for your comment. You can move the Fixed end of the Drag Closer to the Y-Plate, I wouldn’t go no closer than 45mm, to leave room for the controller

Robert -

Which is the longest wire 5 or 6 as my clips come off and I’m not certain I’ve got them the right way round

Rob Thompson - Resolved on Release Reply